To get more information about PET Blowing Mold and Rotary Blow molder

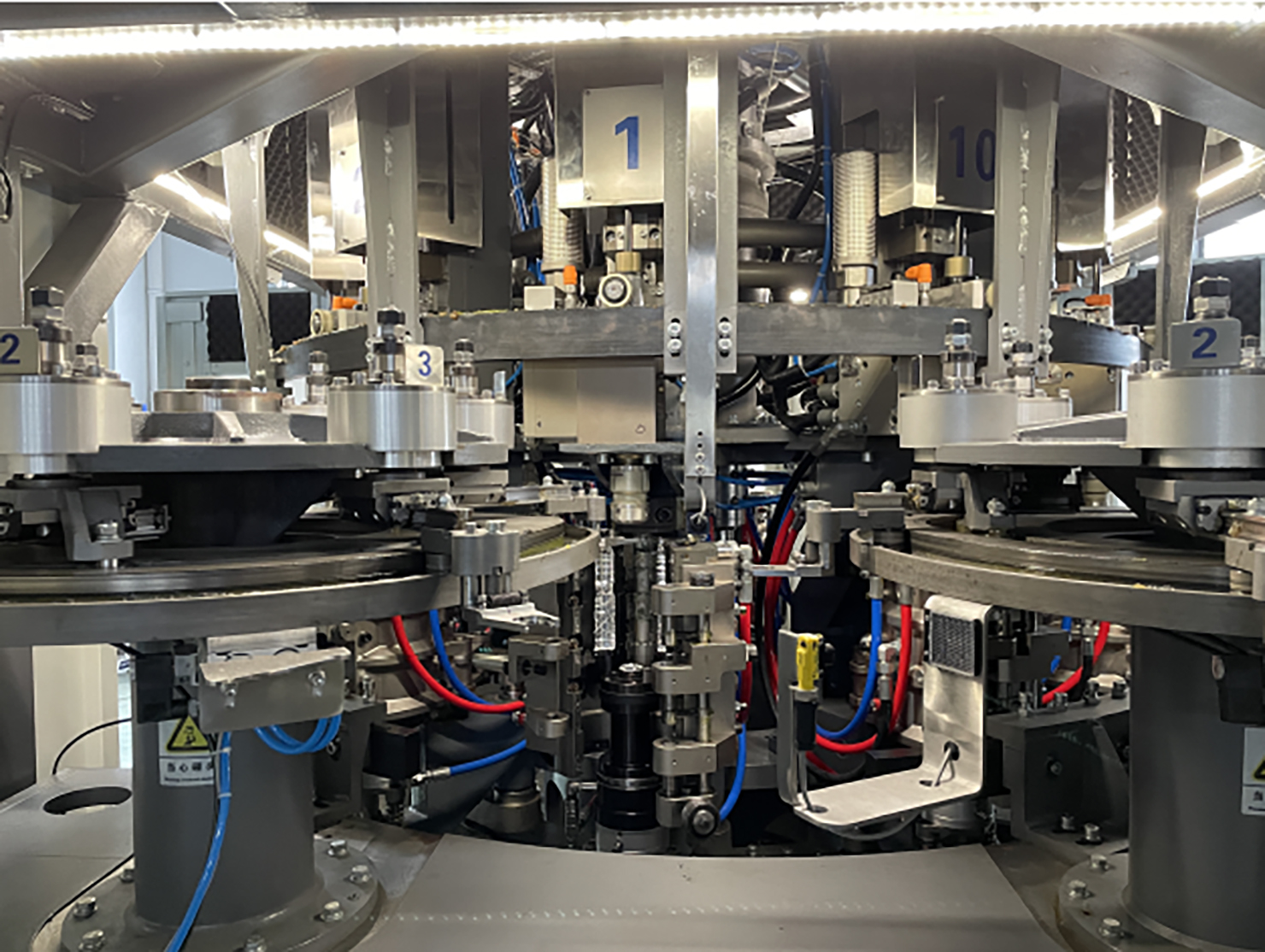

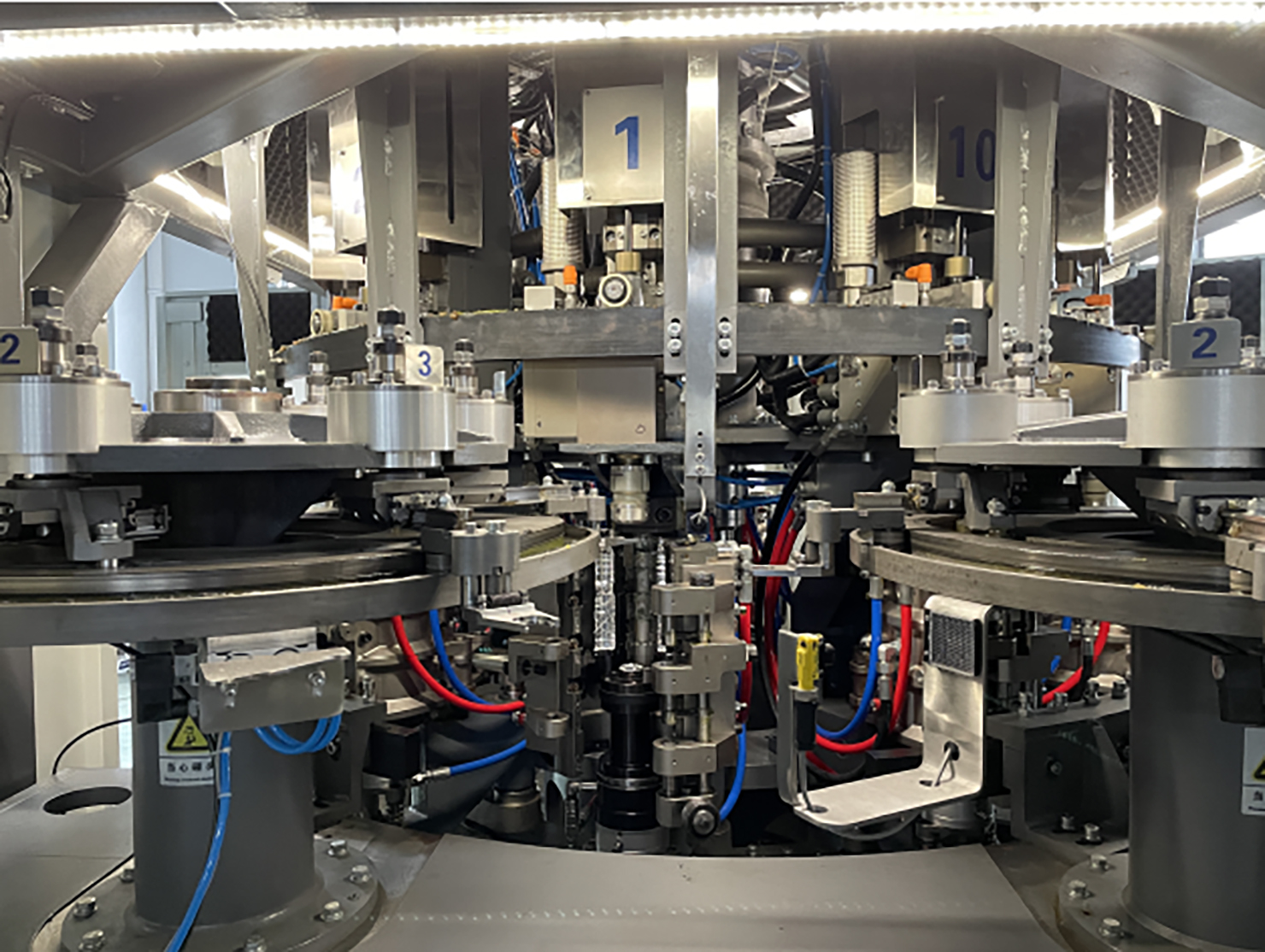

The rotary blowing mold for blow molder is a crucial component in the production of PET (polyethylene terephthalate) bottles and containers. This innovative technology has revolutionized the PET blowing process, offering numerous advantages in terms of efficiency, productivity, and quality.

PET blowing molds are designed to shape molten PET material into the desired bottle or container shape. The rotary blowing molder utilizes a rotating mechanism to optimize the blowing process, resulting in faster production cycles and higher output capacity. This technology is particularly beneficial for manufacturers seeking to streamline their production lines and meet the growing demand for PET packaging solutions.

One of the key benefits of the rotary blowing mold for blow molder is its ability to enhance production efficiency. By utilizing a rotary mechanism, the mold can accommodate multiple cavities, allowing for simultaneous molding of multiple containers. This significantly reduces cycle times and increases overall production efficiency, enabling manufacturers to meet tight deadlines and fulfill large orders with ease.

Furthermore, the rotary blowing molder offers superior precision and consistency in the molding process. The rotating mechanism ensures uniform distribution of the PET material, resulting in consistent wall thickness and overall product quality. This is essential for producing high-quality PET bottles and containers that meet industry standards and consumer expectations.

In addition to efficiency and quality improvements, the rotary blowing mold for blow molder also contributes to cost savings for manufacturers. The increased production capacity and reduced cycle times result in lower energy consumption and labor costs per unit produced. This makes the technology not only a valuable asset in terms of performance but also a sound investment for businesses looking to optimize their production processes.

Overall, the rotary blowing mold for blow molder represents a significant advancement in PET blowing technology. Its ability to enhance efficiency, quality, and cost-effectiveness makes it a valuable asset for manufacturers in the packaging industry. As the demand for PET bottles and containers continues to grow, the adoption of this innovative technology is poised to play a pivotal role in meeting the evolving needs of the market.

Chinese

Chinese