PET Injection Mold

- The injection mold consists of two parts, one is the hot runner and the other is the cold half mold. It is loaded onto an injection device,and then passed through a blow molding system to create a container for edible or non-edible liquids. (Includes water, soft drinks, milk, alcohol, oils, detergents, personal care products)

PET Blowing Mold

-

The PET bottle blow moulding process works by reheating a pre-moulded PET preform which is then automatically positioned into a mould. High pressure food grade compressed air is then injected into the preform which expands to form the shape of the mould.Application:Water, CSD, HR, Aseptic, Edible oil and other liquid packaging

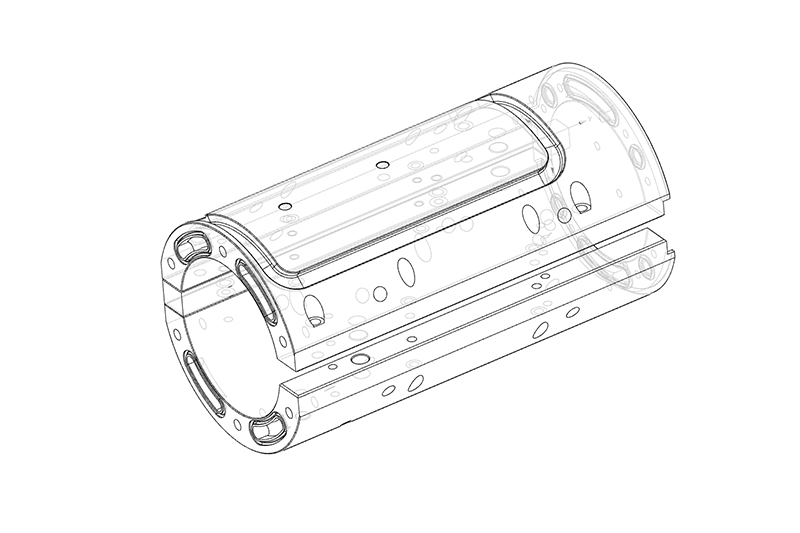

Mold Shell

- The mold shell also call backplate, is the most important part of the rotary PET bottle blowing mold. Has a rapid cooling effect.

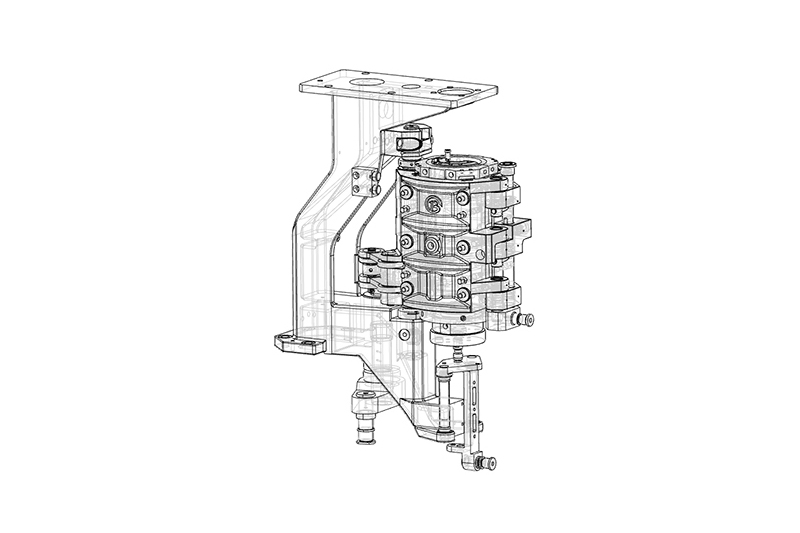

Mold Frame

- The mold frame and mold base are important parts of the rotary bottle-blowing machine. The mold frame is like a manipulator, fixed on the equipment, and its claws are used to install the mold holder.

Closure Mold

- The capping mold is divided into pressure capping mold and injection capping mold. except that instead of the molding material being pressurized in the cavity, it is pressurized in a separate chamber, and then forced through an opening, and into a closed mold. Transfer molds usually have multi-cavities.

CONTACT US

Chinese

Chinese