PET Blowing Mold for Rotary machine

Product Selling Point Introduction

1. BJY has a professional design team.

2. BJY can help you design bottles. Bottle design available for water, juice, carbonated drinks,

and other drinks.

3. BJY can help you test the mold and test the bottles.

4. BJY can help you with repair old mold.

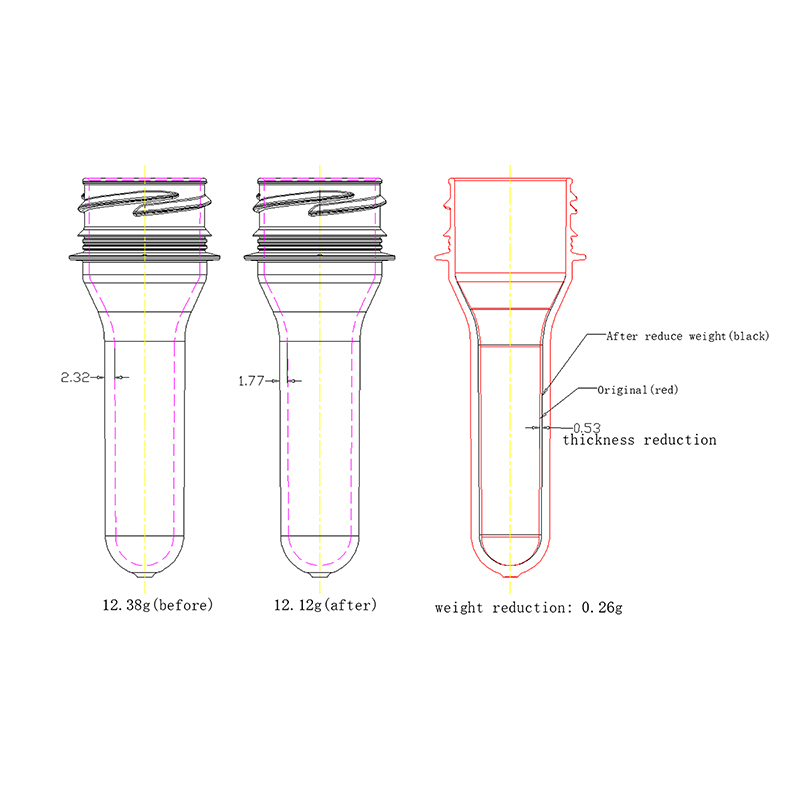

5. BJY can help you with the mold transformation.

Parameter Characteristics Of The Product

| Equipment | Rotary Blowing Machine |

| Available Machine Brand | SIDLE, KRONES, SIPA, KHS, SACMI, TECH-LONG, NEWAMSTAR, etc. |

| Volume | 50ml ~ 2500ml |

| Material | S136 for cavity, A6061 for base |

|

Gurantee |

5 Million Cycle Times |

| Application | Water, CSD, HR, Aseptic, Edible oil and other liquid packaging |

Popular Science Product Knowledge

What is this Rotary Blowing Mold?

Rotary Blowing mold is one of important components of the Rotary blowing molder. it has high production capacity, high-quality, low maintenance and safety characteristics.

What is the difference between hot filling mold and cold filling mold?

How hot can pet bottles get?

Hot-fill PET plastic bottles are designed to withstand temperatures of up to 185 degrees Fahrenheit, making them ideal for various applications that other plastics can't handle. One common use for a hot-fill bottle is in the food industry.

description2

Chinese

Chinese