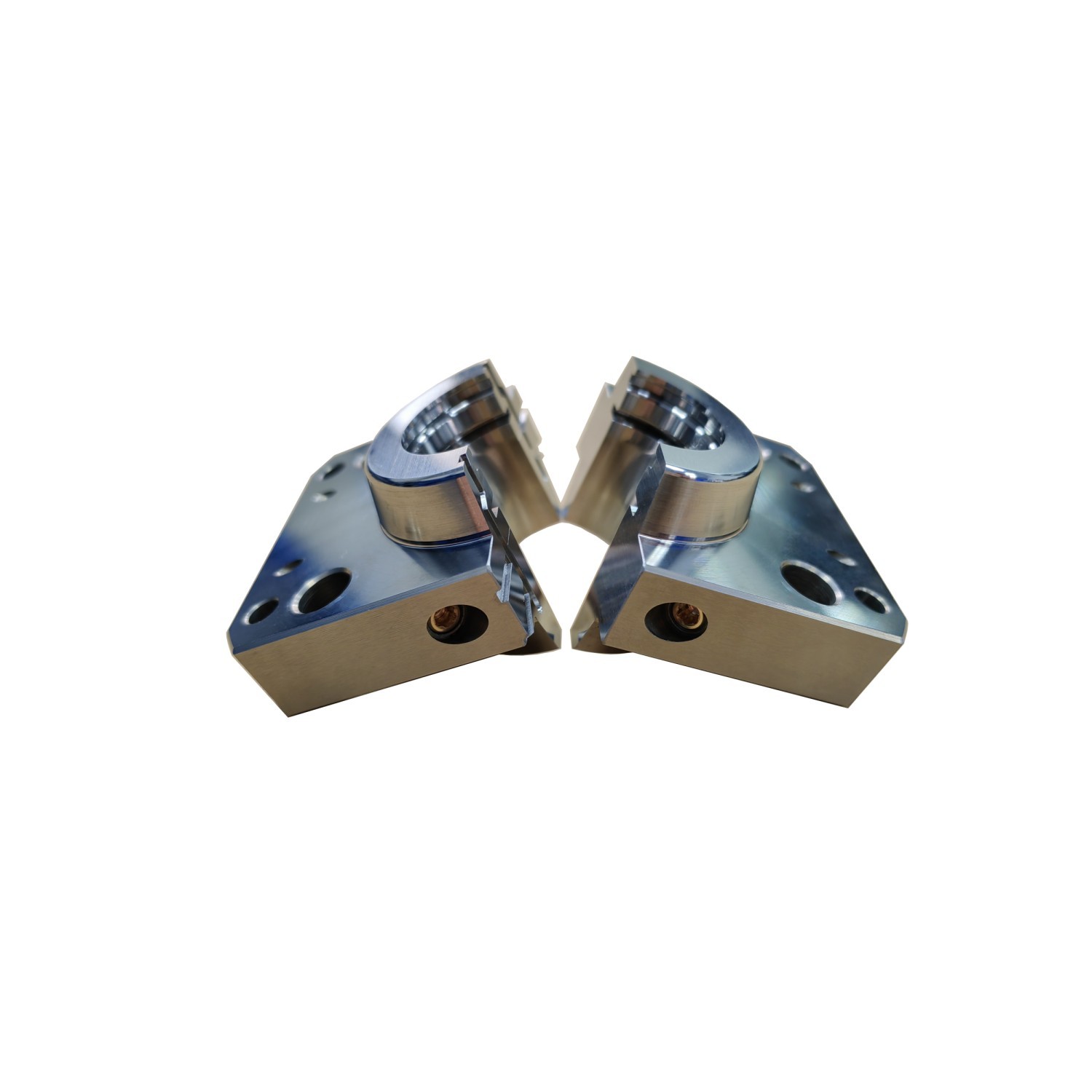

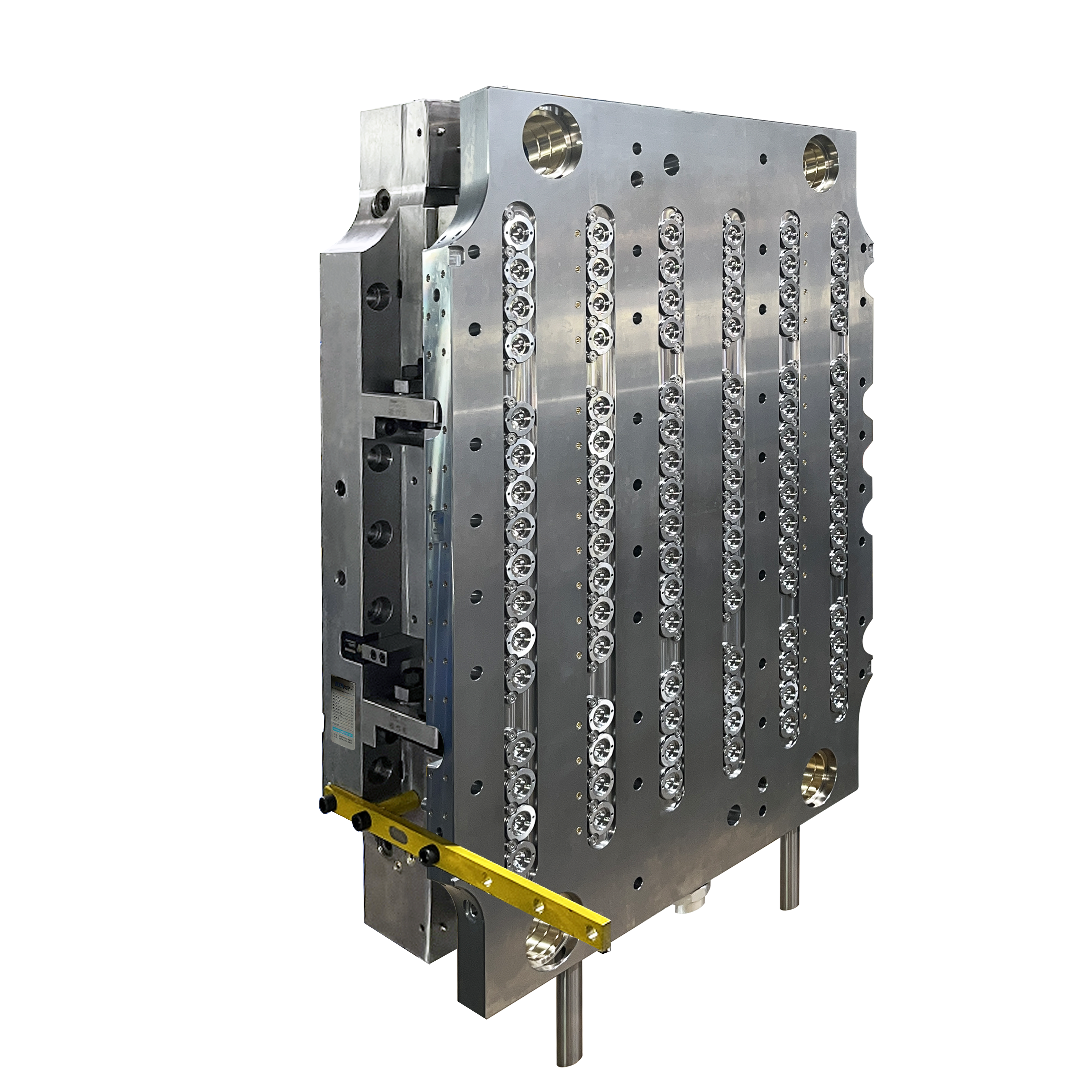

13.5g Cavity Flange

Product Features

Application Scenarios

Beverage Preform High-Efficiency Production

Adapted for 13.5g standard preform manufacturing, meeting high-speed injection molding demands for mineral water and carbonated beverage bottles.

High-Temperature Fill Container Molding

Heat-resistant runner design compatible with 85℃ hot-fill processes for tea and juice bottle preforms.

Household & Personal Care Bottle Production

Precise control of neck threads and sealing surfaces ensures leak-proof packaging for lotions and detergents.

Equipment Maintenance & Upgrades

Provides cost-effective cavity replacement solutions for injection molding systems, reducing spare parts costs.

Cross-Border Flexible Production

Compatible with multi-brand equipment lines in Southeast Asia, the Middle East, and similar regions, supporting rapid mold change requirements.

Service Process

description2

Chinese

Chinese