0102030405

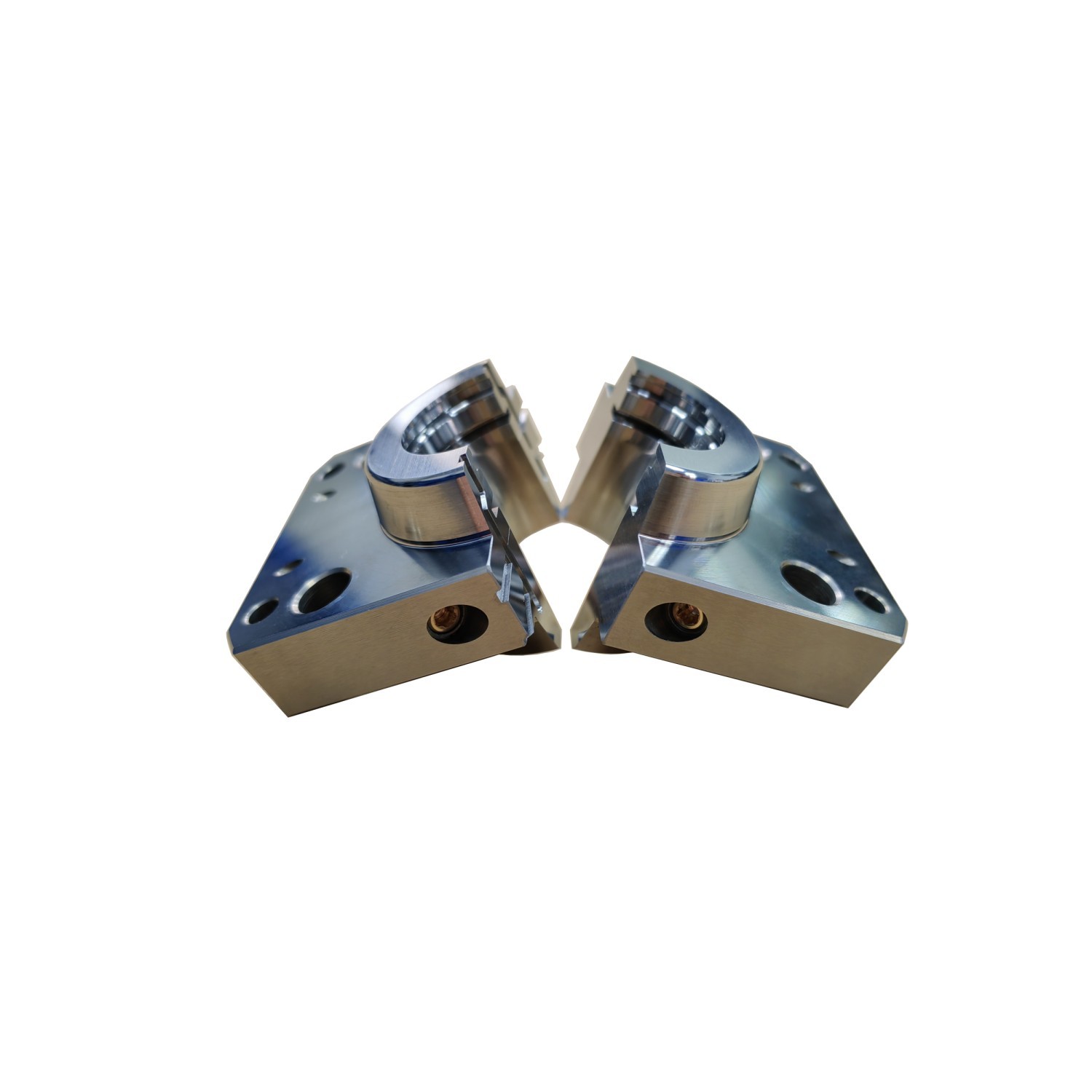

16.76g Cavity

Product Features

Precision Molding Technology

Utilizes imported high-hardness mold steel to enhance cavity wear resistance and corrosion protection, significantly extending mold service life.

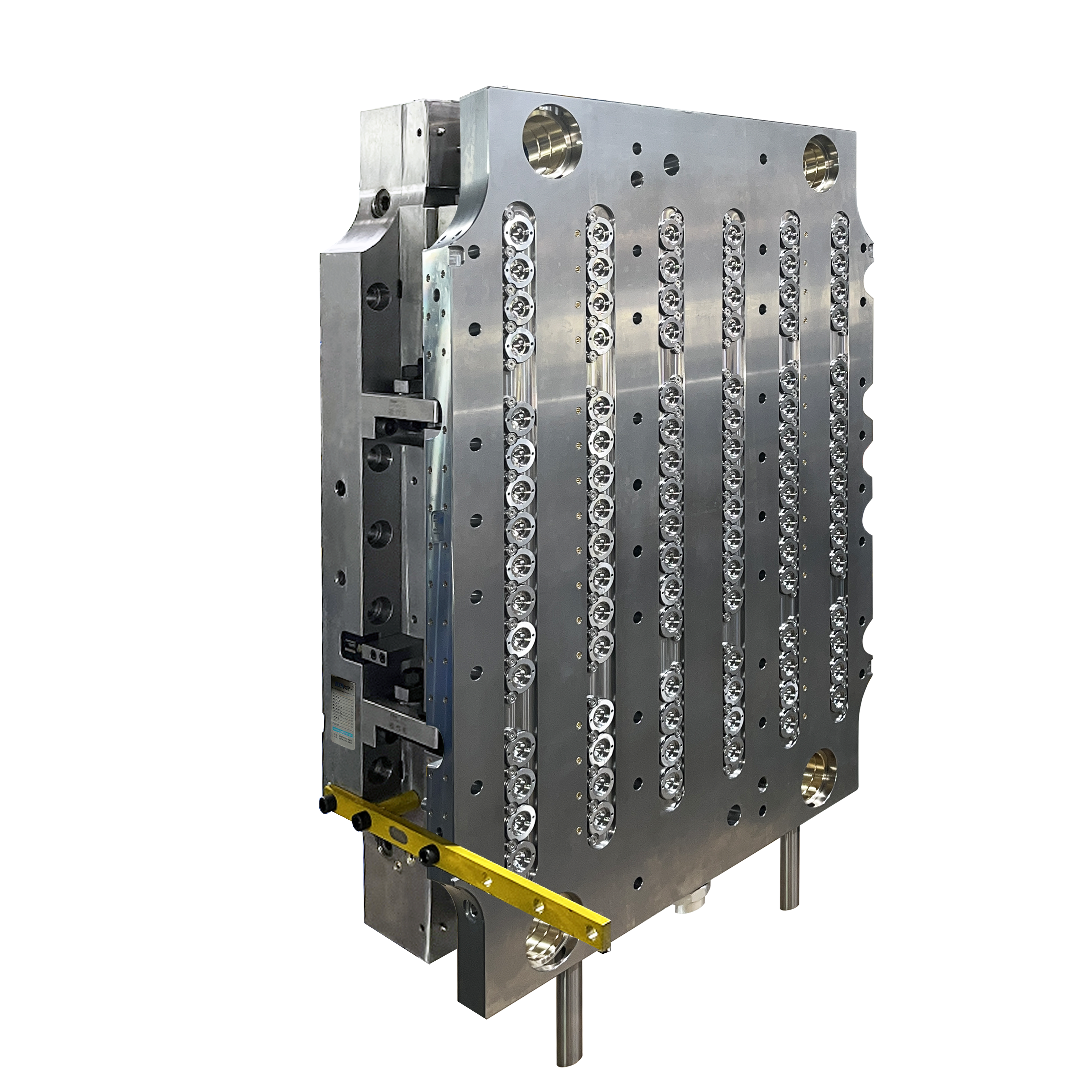

High-Efficiency Multi-Cavity Design

Supports flexible cavity configurations (from 16 to 144 cavities) and integrates a hot runner system to minimize material waste and improve production efficiency.

Flexible Adaptation and Customization

Mold dimensions and runner layouts can be customized based on client equipment specifications. Compatible with various neck finishes including PCO1881 and ROPP. Reverse engineering of samples and production plan optimization are also supported.

Application Scenarios

Food & Beverage Industry

Designed for the production of lightweight preforms used in mineral water bottles, juice bottles, and edible oil containers. Meets high hygiene standards and pressure resistance requirements.

Personal Care & Pharmaceutical Packaging

Suitable for small-neck preforms used in cosmetic and pharmaceutical bottles, ensuring tight sealing performance and dimensional accuracy.

Industrial Packaging Applications

Ideal for preforms used in chemical containers, compatible with PET and PET/PC alloy materials. Offers excellent resistance to low temperatures and chemical corrosion.

Service Process:

1. Sample-Based Workflow

① Customer provides sample → ② BJY Baijinyi conducts reverse engineering → ③ Deliver 2D/3D drawings for confirmation → ④ Confirmation completed → ⑤ Order placement → ⑥ Production workshop manufacturing → ⑦ Quality inspection → ⑧ Qualified shipment.

description2

Chinese

Chinese