0102030405

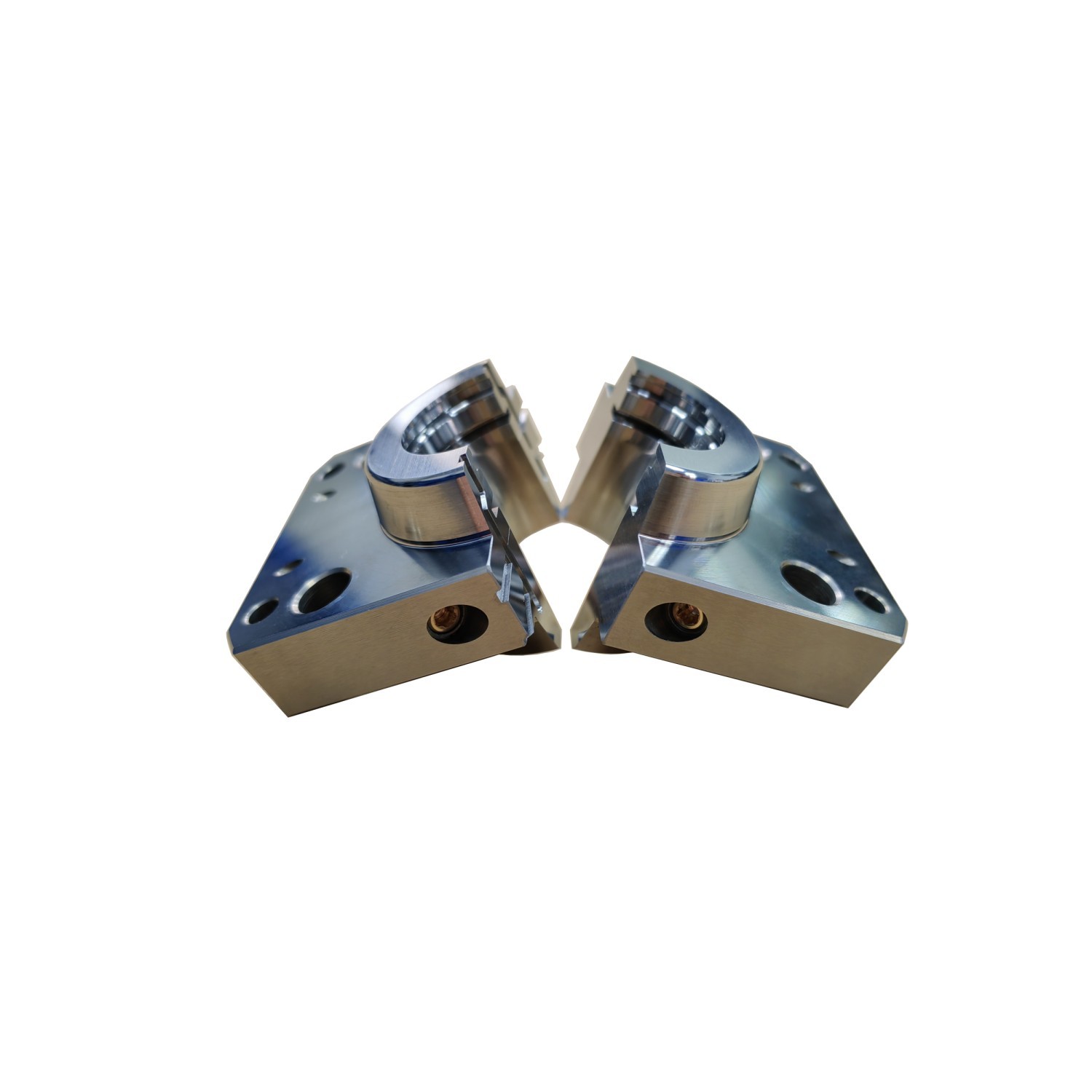

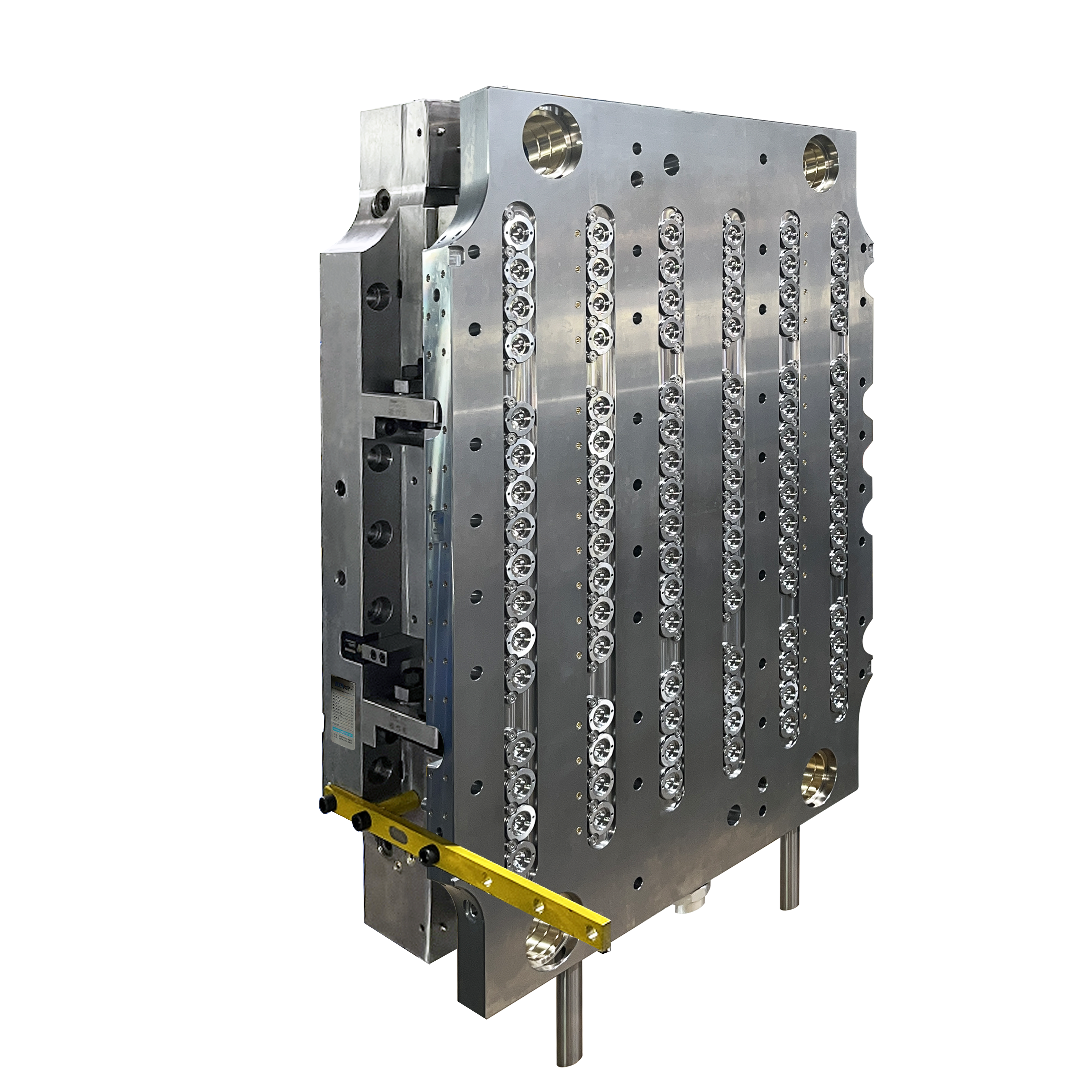

310ML Aluminum PET Bottle Blow Mold

Product Features

High Thermal Conductivity:

The aluminum alloy material offers excellent heat transfer capabilities, accelerating preform cooling and boosting production efficiency.

Lightweight Design:

Weighing approximately one-third of a steel mold of the same specification, it reduces equipment load and extends machine lifespan.

Modular Structure:

Supports quick cavity replacement to accommodate various bottle types, enhancing production line flexibility.

Precision Machining:

CNC machining ensures uniform bottle wall thickness and smooth surfaces, improving overall product quality.

Surface Treatment:

Optional anodizing enhances corrosion and wear resistance, significantly extending mold service life.

Application Scenarios

Suitable for producing 310ml PET bottles, this mold is widely used in beverage packaging for drinking water, juice, tea, and more. It is especially ideal for production lines requiring frequent bottle changeovers and for manufacturers who prioritize production efficiency and product quality.

Note

This product is engineered to be compatible with various injection molding systems and is not affiliated with or endorsed by any specific brand.

Service Process:

1. Sample-Based Workflow

① Customer provides sample → ② BJY Baijinyi conducts reverse engineering → ③ Deliver 2D/3D drawings for confirmation → ④ Confirmation completed → ⑤ Order placement → ⑥ Production workshop manufacturing → ⑦ Quality inspection → ⑧ Qualified shipment.

description2

Chinese

Chinese