0102030405

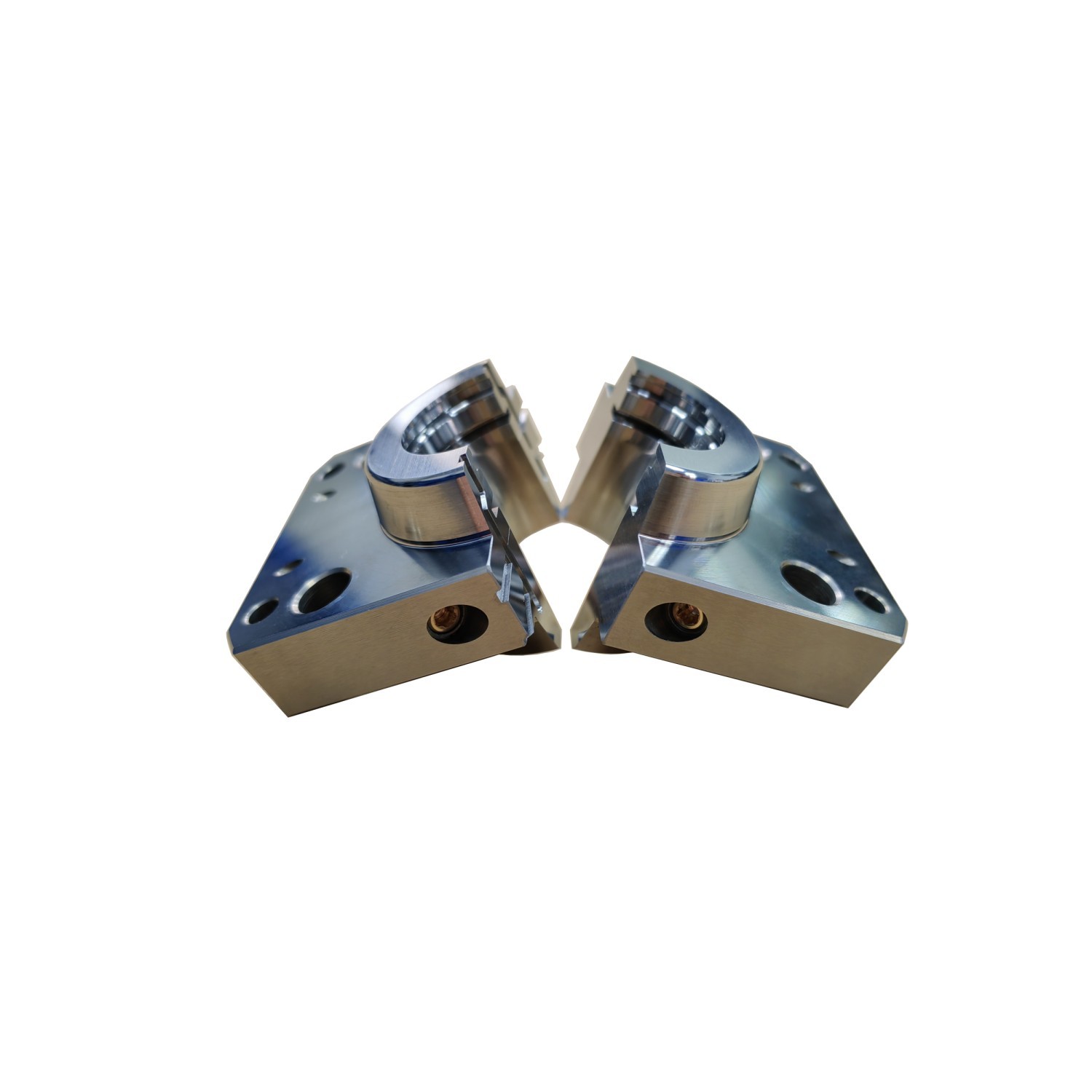

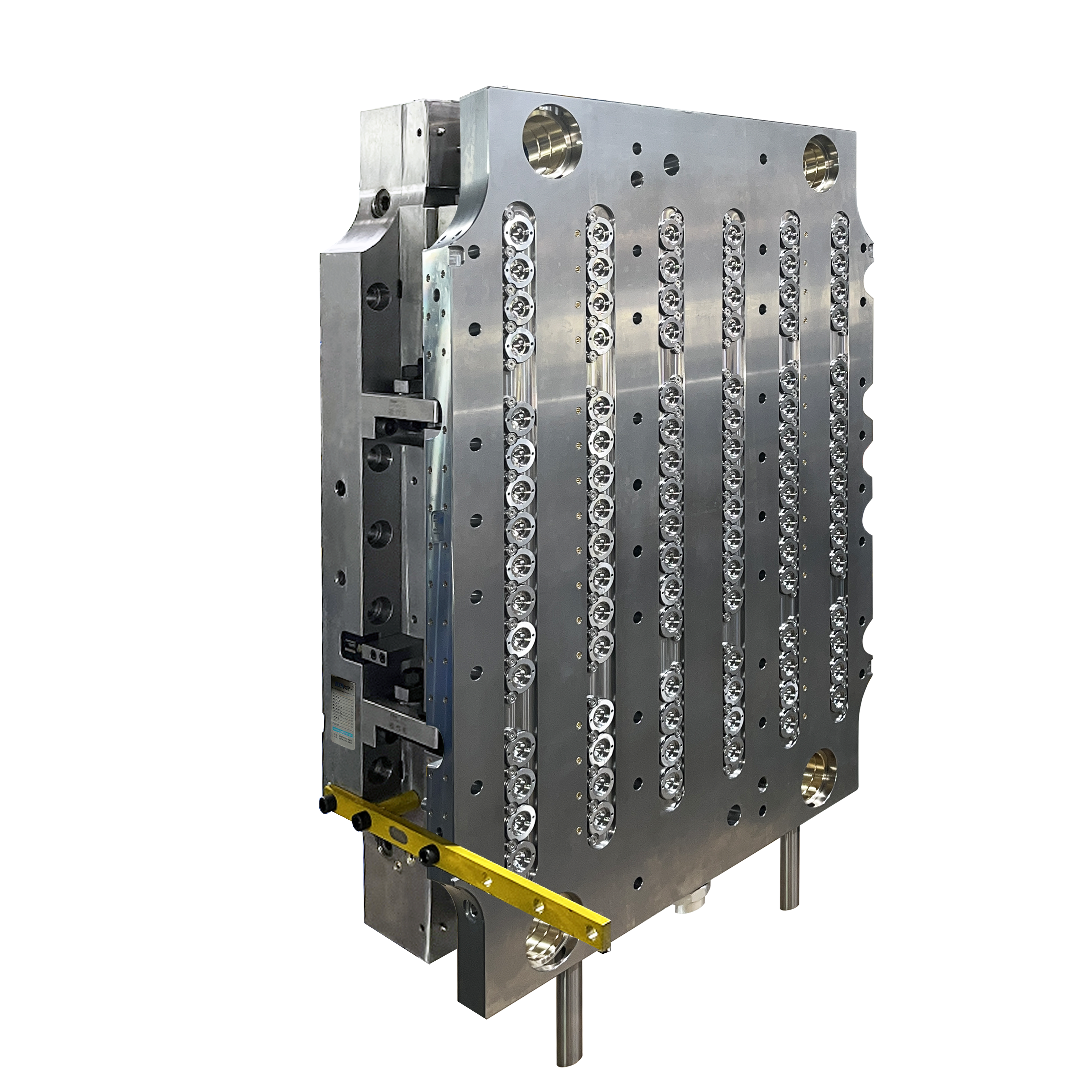

500ml Aluminum Blow Mold

Product Features

Lightweight High-Efficiency Design

High-strength aluminum construction reduces weight compared to traditional steel molds, lowering equipment load and enhancing production cycle efficiency.

Precision Molding Assurance

Mirror-polished cavity surfaces ensure bottle transparency ≥92% and zero deviation in label positioning.

Rapid Heat Dissipation Performance

Aluminum's inherent high thermal conductivity, combined with honeycomb cooling channels, shortens bottle solidification time.

Corrosion-Resistant Durable Structure

Anodized hardening surface treatment resists corrosion from sugary and acidic liquid environments, extending service life.

Global Compliance Interface

Mold base clamping force and hot runner parameters adapt to multinational equipment standards.

Application Scenarios

Carbonated Beverage High-Speed Production Lines

Optimized for 500ml bottle production of carbonated drinks (e.g., cola, sparkling water).

Juice & Tea Beverage Contract Manufacturing

Compatible with ambient-fill processes, ensuring shelf-life stability.

Cross-Border Lightweight Upgrade Solutions

Provides low-energy-consumption mold systems for regions with unstable power supplies (e.g., Southeast Asia, Africa).

Bottled Water Mass Production

Adapts to large-volume water containers and small-bottle production lines, enabling rapid capacity switching.

Equipment Life-Extension Retrofitting

Replaces aging molds to reduce maintenance costs and upgrade blow molding machine efficiency.

Service Process

1. Sample-Based Workflow

① Customer provides sample → ② BJY Baijinyi conducts reverse engineering → ③ Deliver 2D/3D drawings for confirmation → ④ Confirmation completed → ⑤ Order placement → ⑥ Production workshop manufacturing → ⑦ Quality inspection → ⑧ Qualified shipment.

description2

Chinese

Chinese