0102030405

500ml Aluminum Blow Mold

Product Features

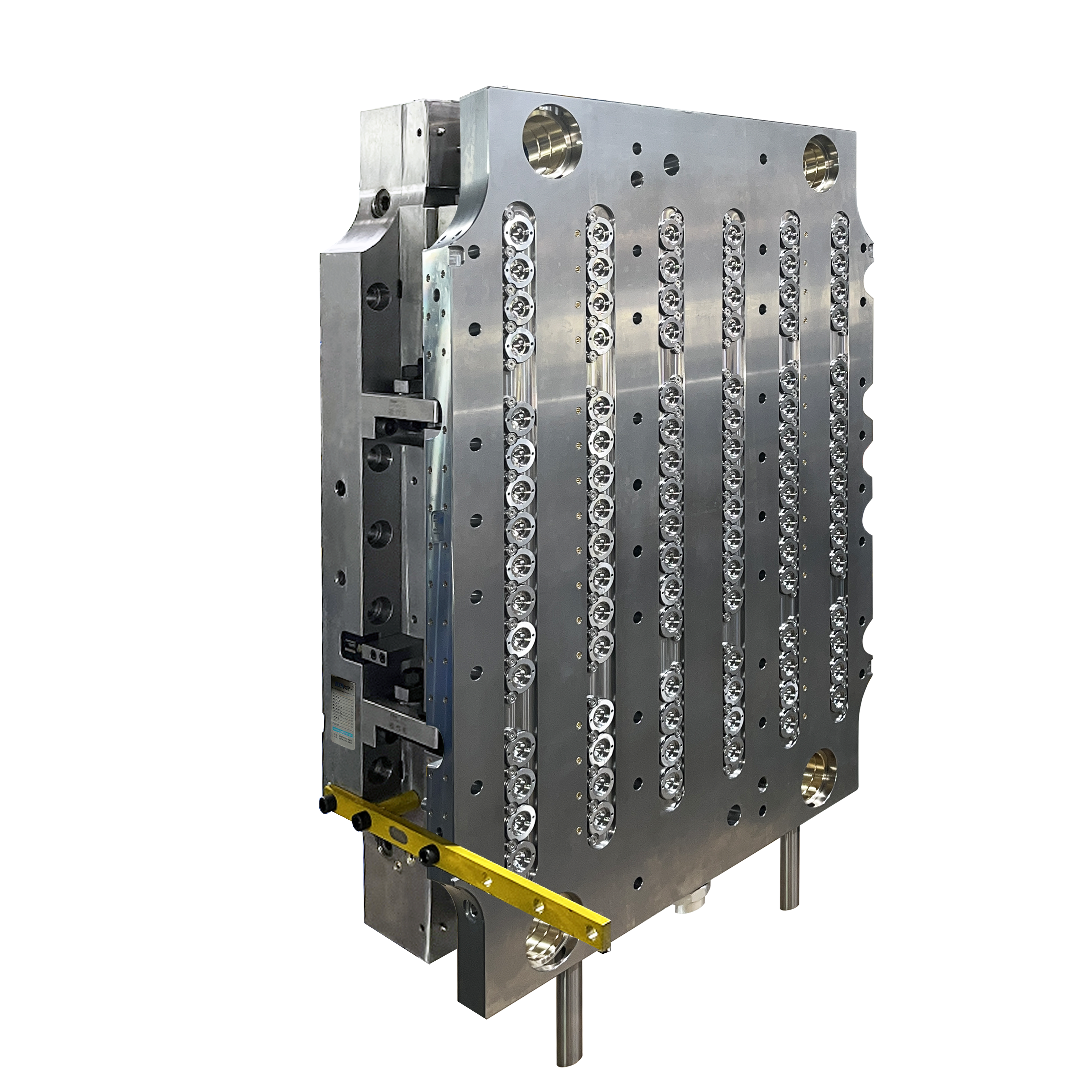

Lightweight, High-Efficiency, and Energy-Saving Design

The imported aluminum material significantly reduces weight compared to traditional molds, lowering equipment operational load and improving production line cycle efficiency.

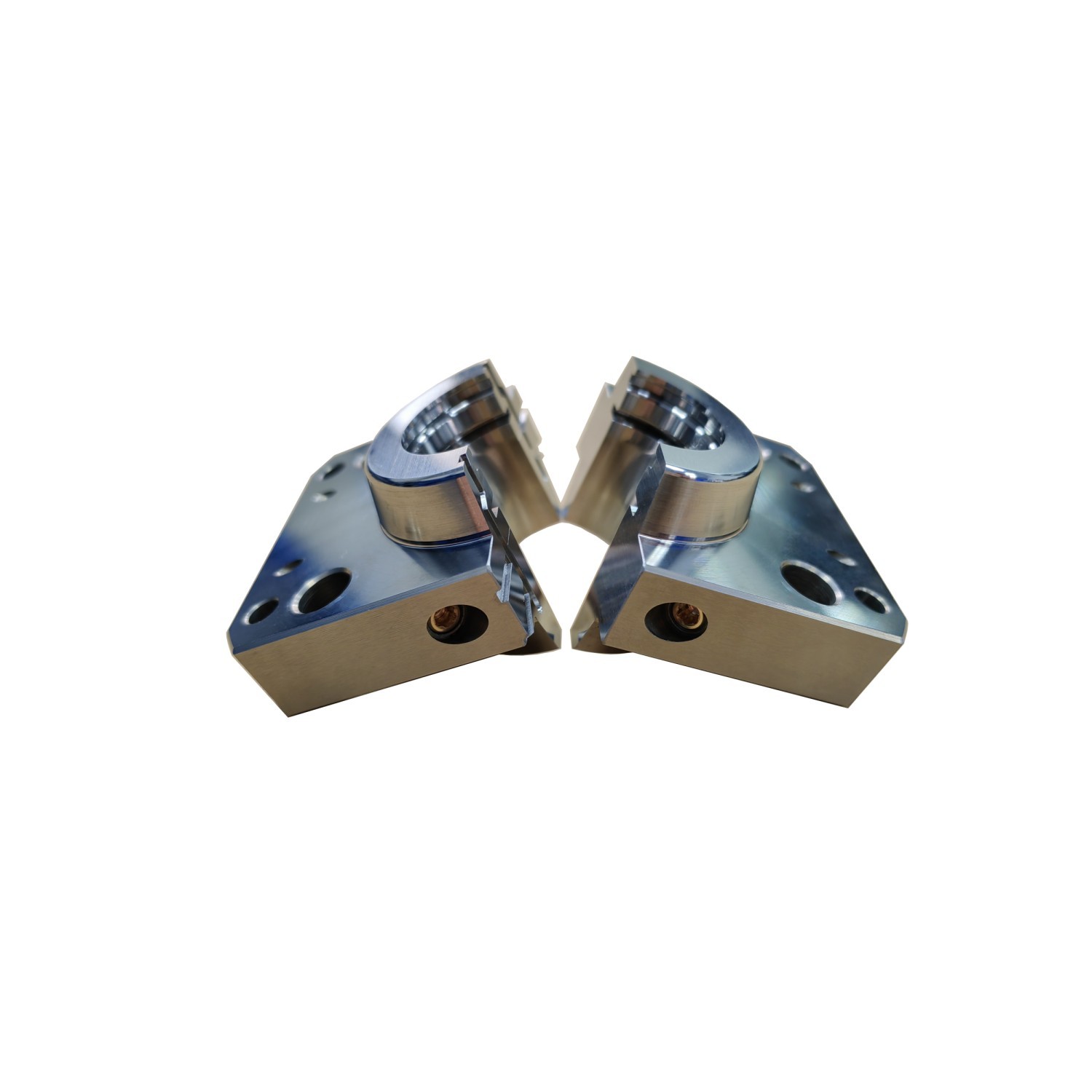

Precision Bottle Neck Formation

Mirror-polished cavities and contoured runner design ensure minimal vertical deviation in bottle neck threads and airtight sealing compliance.

Dynamic Heat Dissipation Optimization

Multi-channel cooling systems synergize with aluminum’s inherent high thermal conductivity, shortening bottle solidification time.

Corrosion-Resistant Surface Treatment

Anodized hardening resists erosion from sugary and acidic liquid environments, extending service life.

Global Standard Compatibility

Mold base clamping force and temperature control logic align with multinational equipment specifications.

Application Scenarios

Functional Beverage Mass Production

Adapted for 500ml bottle production of energy drinks and electrolyte water.

Cross-Border Flexible OEM Production Lines

Provides low-energy-consumption, easy-to-maintain mold upgrade solutions for contract manufacturers in Southeast Asia and the Middle East.

Flavored & Sparkling Water Solutions

Ensures precise control of uniform bottle wall thickness, compatible with emerging categories like fruit-flavored sparkling water and alkaline water packaging.

Equipment Efficiency Retrofitting

Replaces aging steel molds to extend blow molding equipment lifespan and reduce operational costs.

Multi-Climate Environment Adaptability

Temperature resistance ranges from -15°C to 75℃, ensuring stable performance in high-humidity production environments.

Service Process

1. Sample-Based Workflow

① Customer provides sample → ② BJY Baijinyi conducts reverse engineering → ③ Deliver 2D/3D drawings for confirmation → ④ Confirmation completed → ⑤ Order placement → ⑥ Production workshop manufacturing → ⑦ Quality inspection → ⑧ Qualified shipment.

description2

Chinese

Chinese