0102030405

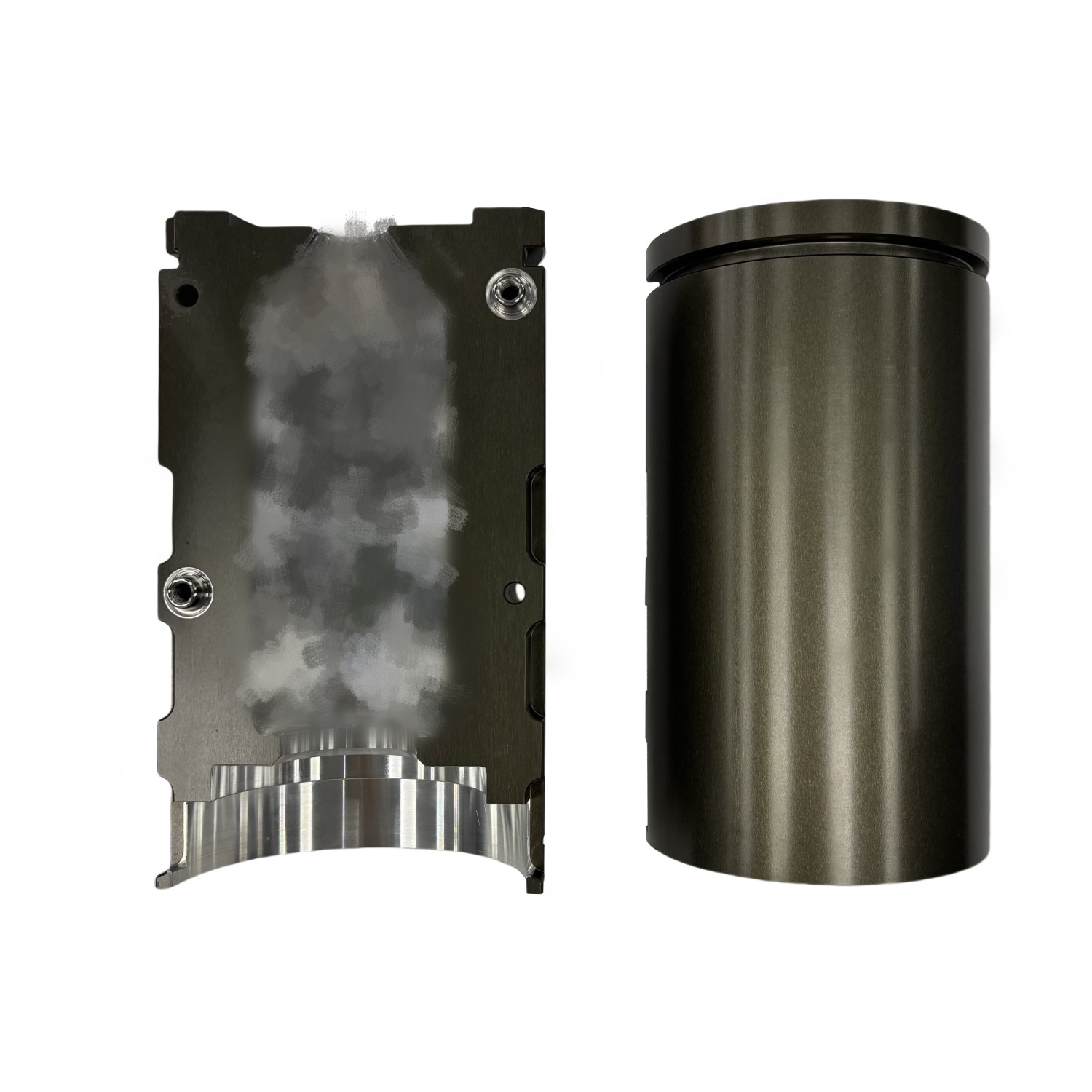

500ml Fourth Generation Aluminum Mold

Product Features

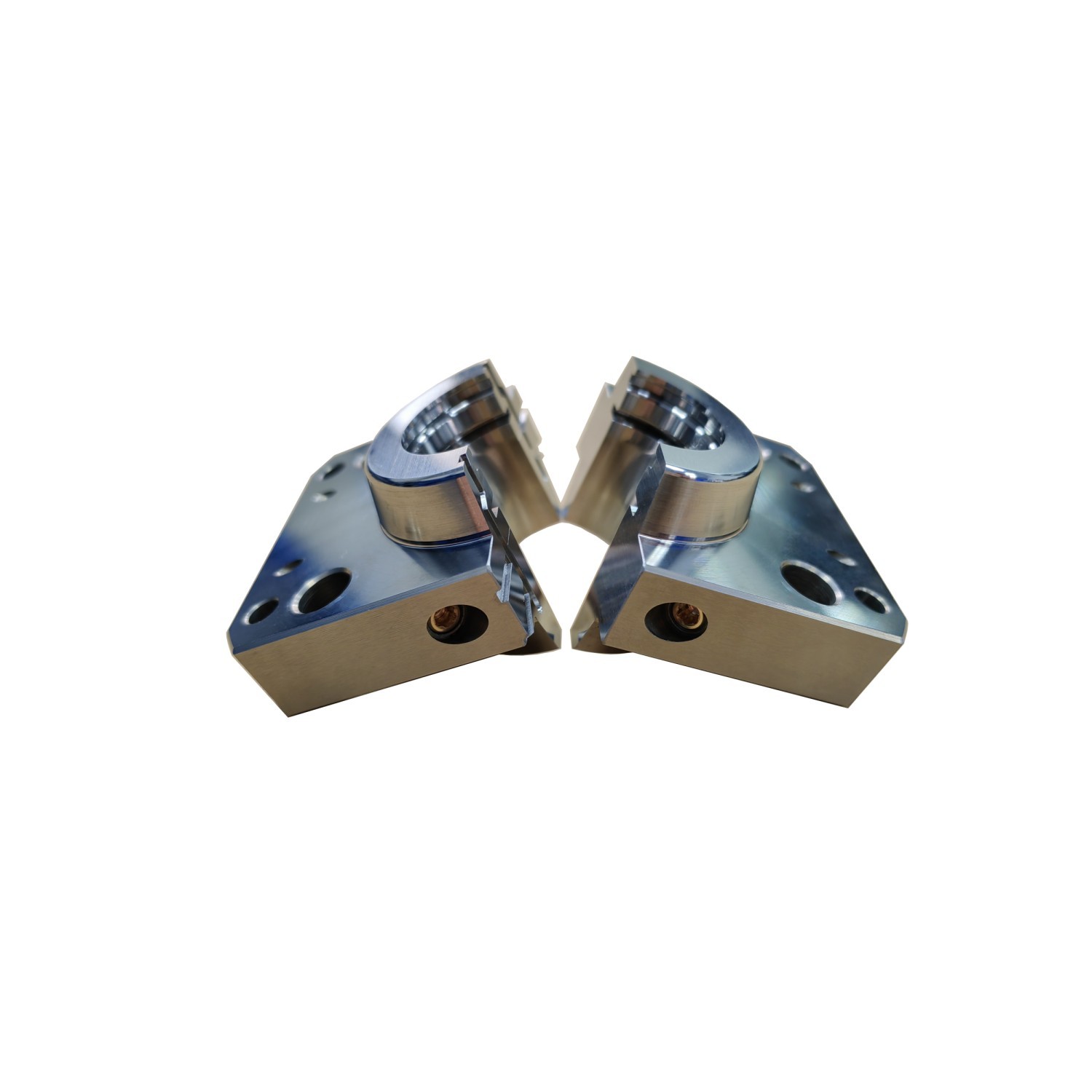

Dynamic Balancing Clamping System

The cavity pressure distribution simulates the operational logic of fourth-generation equipment, eliminating eccentric stress to ensure uniform bottle wall thickness.

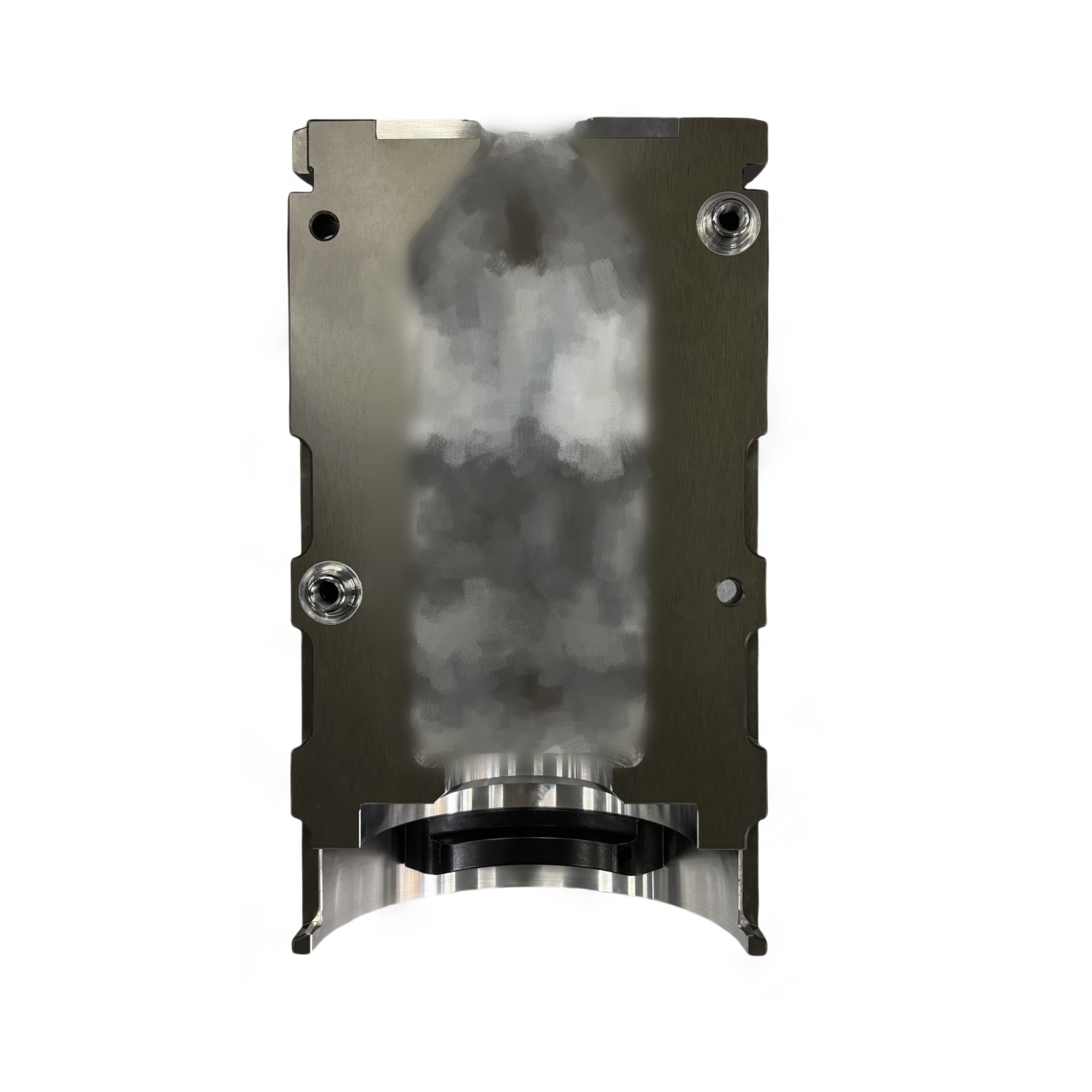

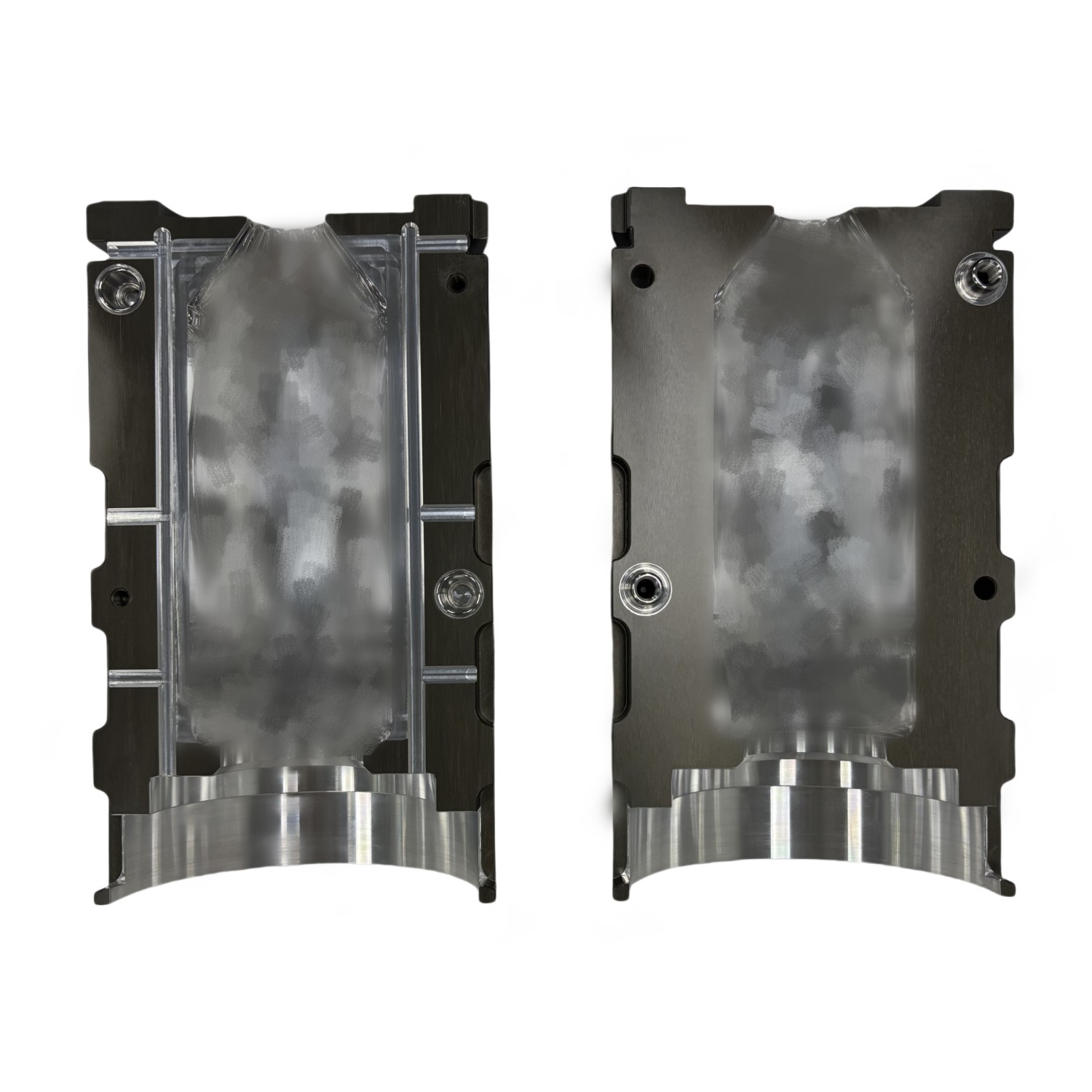

High-Efficiency Heat Dissipation

Aluminum material combined with optimized cooling channels enhances heat dissipation efficiency, shortening the molding cycle.

Corrosion-Resistant Composite Coating

Anodized surface treatment resists erosion from sugary/acidic liquids.

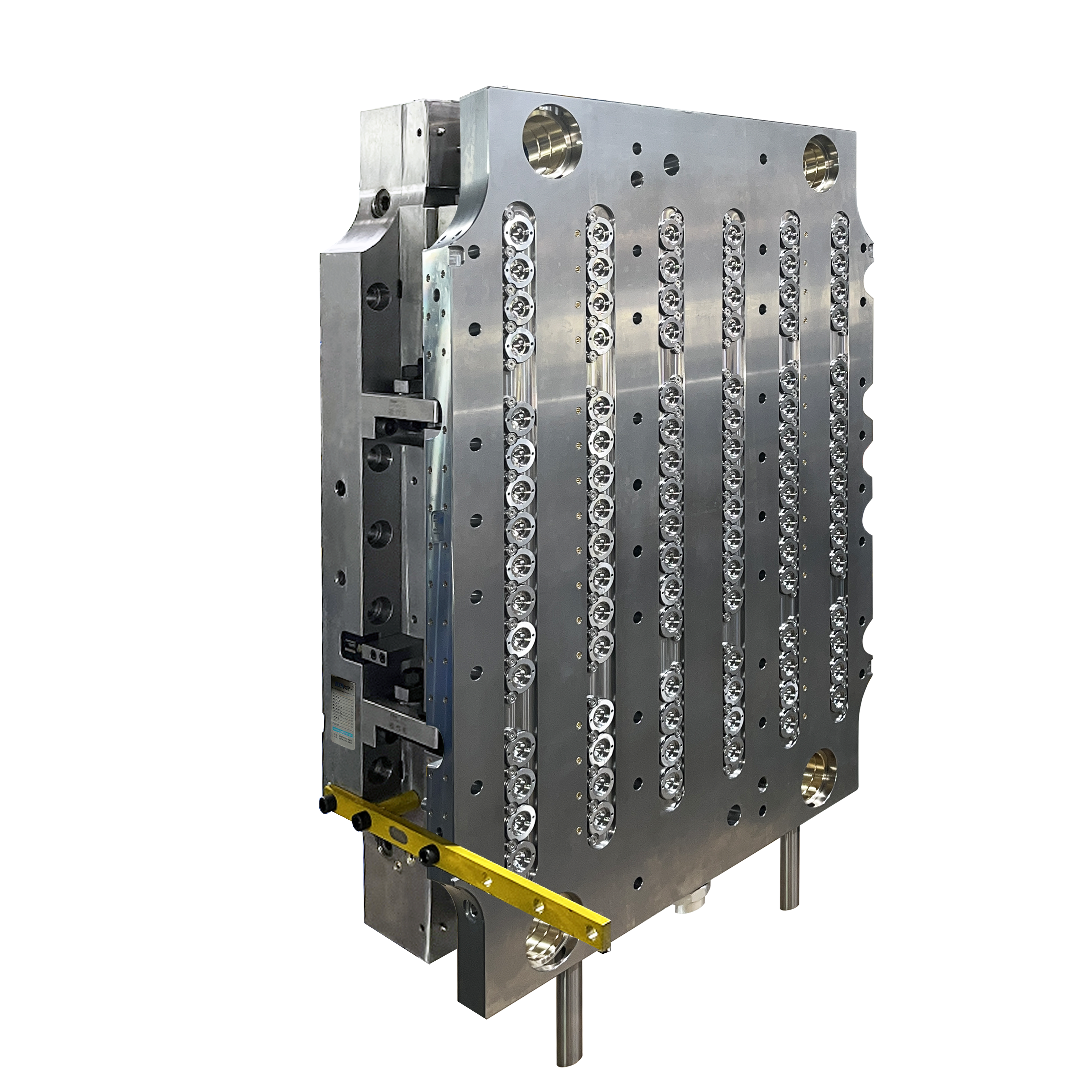

Intelligent Quick-Change Interface

Modular alignment pins and standardized hot runner interfaces enable multi-profile switching (500ml-1.5L) within 15 minutes.

Application Scenarios

High-Pressure Carbonated Beverage Mass Production

Adapted for pressure-resistant requirements of carbonated beverages (e.g., cola, sparkling water), achieving industry-standard bottle neck sealing performance.

Cross-Border Flexible OEM Production Lines

Provides fourth-generation equipment-compatible solutions for contract manufacturers in Southeast Asia and Latin America, reducing mold procurement costs.

Functional Transparent Bottle Production

Bottle transparency ≥95%, ideal for premium product shelf display (e.g., NFC juices, collagen drinks).

Equipment Efficiency Upgrade

Replaces aging steel molds and adapts to fourth-generation blow molding machine energy-saving retrofits, lowering comprehensive energy consumption.

Extreme Climate Adaptability

Compatible with stable operation in high-temperature Middle Eastern and low-temperature Nordic environments.

Service Process

1. Sample-Based Workflow

① Customer provides sample → ② BJY Baijinyi conducts reverse engineering → ③ Deliver 2D/3D drawings for confirmation → ④ Confirmation completed → ⑤ Order placement → ⑥ Production workshop manufacturing → ⑦ Quality inspection → ⑧ Qualified shipment.

description2

Chinese

Chinese