0102030405

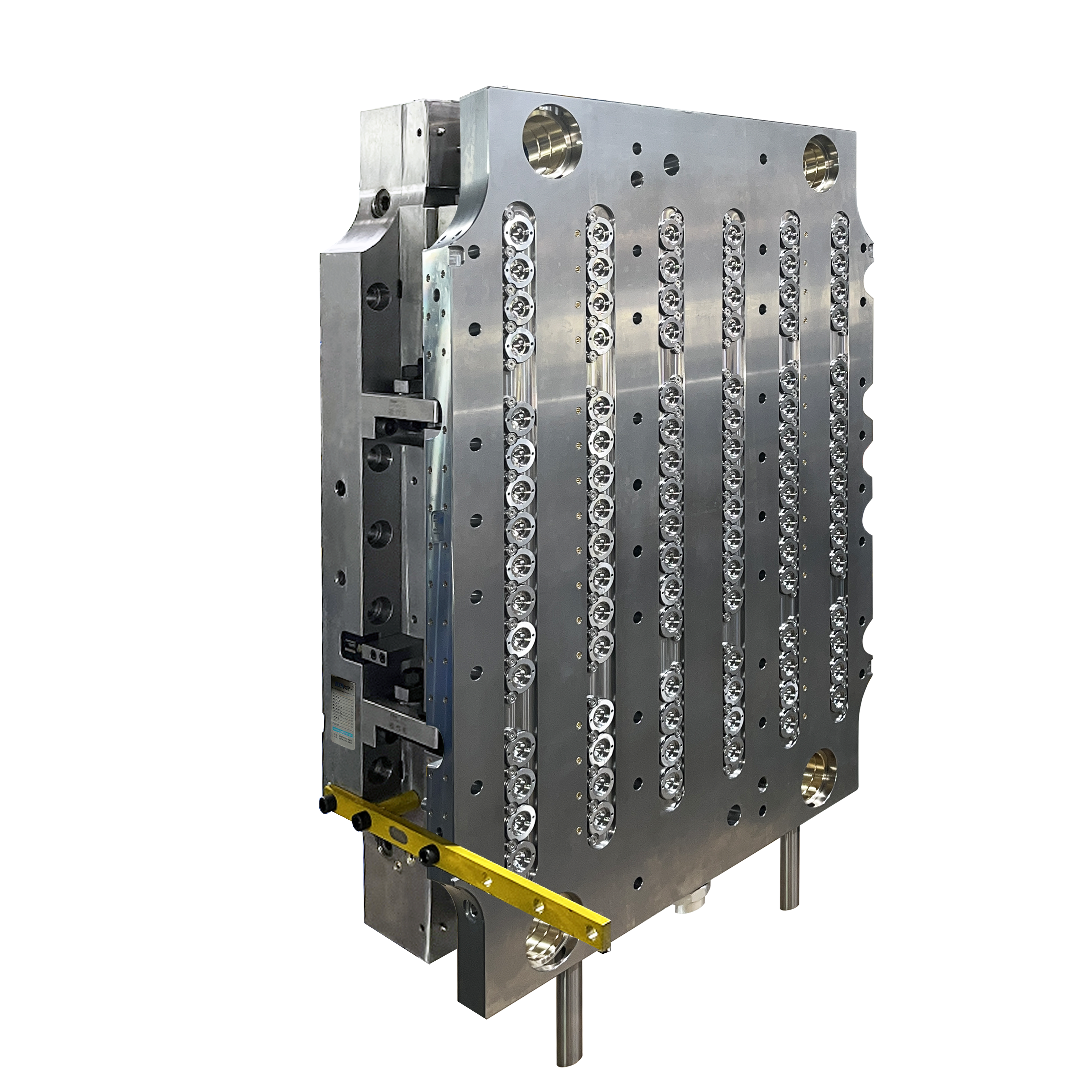

500ml Hot-Fill PET Blow Mold

Product Features

Industrial-Grade Compatibility

Precision-engineered mounting interfaces and thermal logic synchronization for seamless integration with advanced blow molding systems.

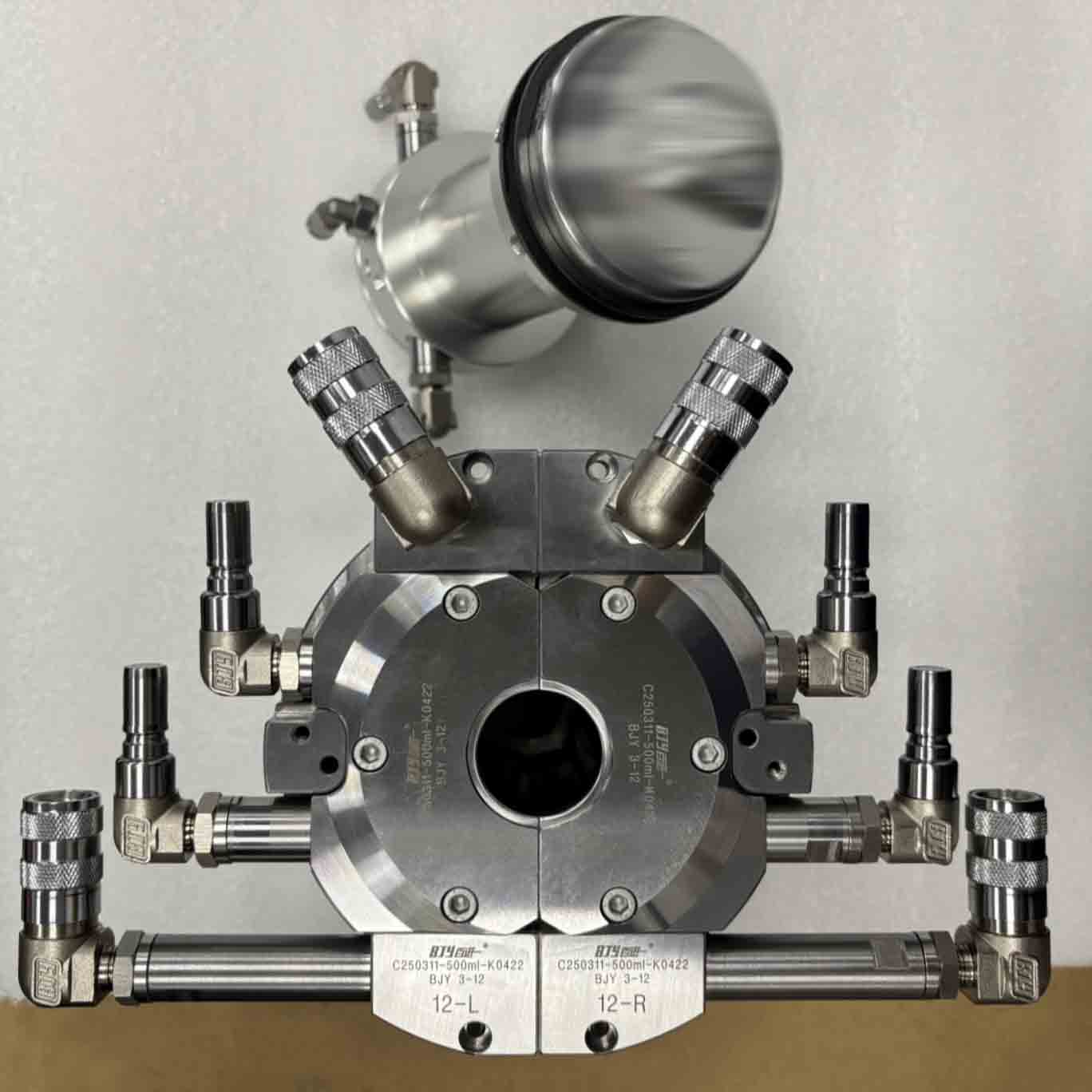

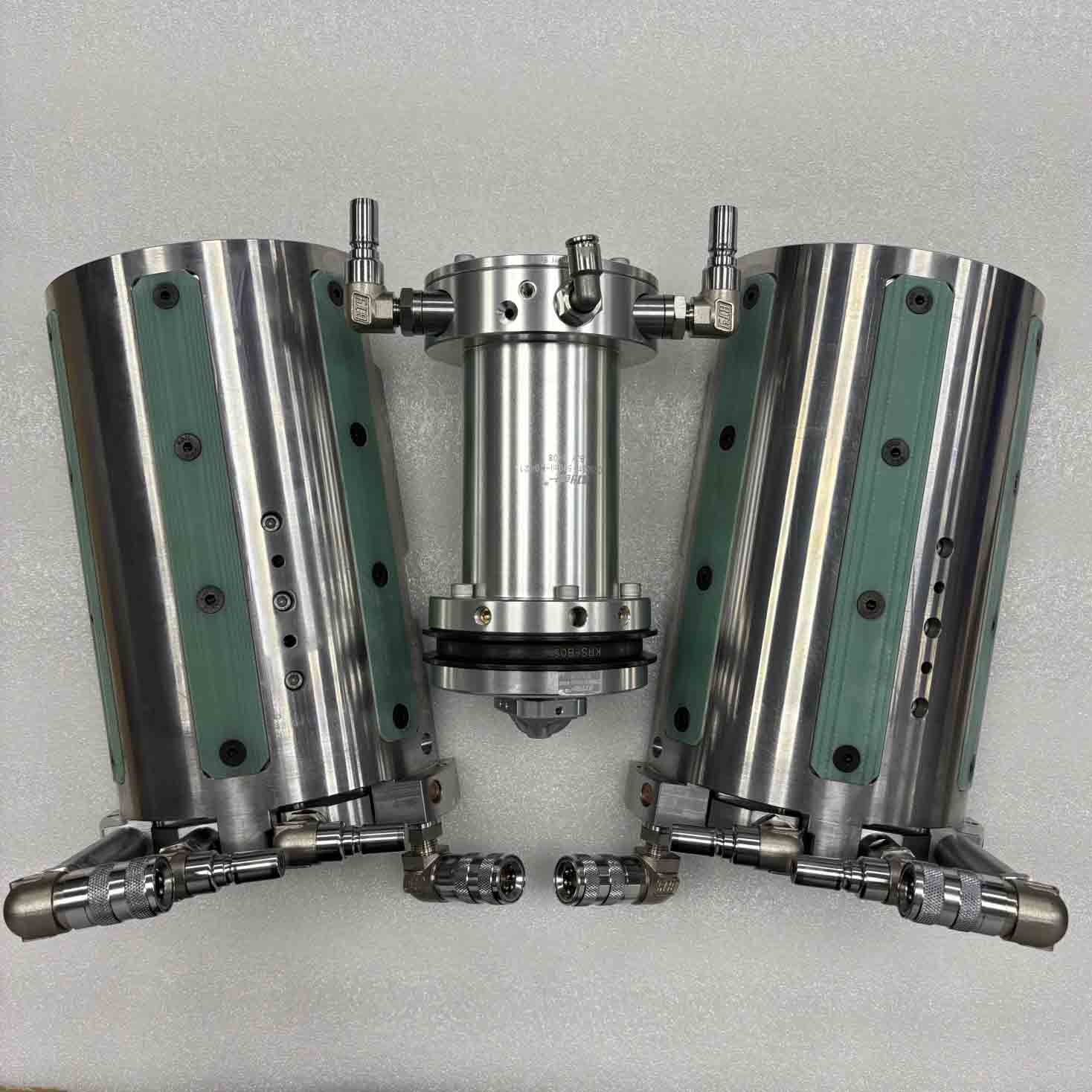

Hot-Fill Durability

Multi-layer surface hardening technology resists thermal deformation and chemical corrosion in high-temperature, high-acidity environments.

Uniform Wall Thickness Control

Optimized cavity geometry with multi-zone cooling channels ensures consistent bottle wall distribution (±0.1mm tolerance).

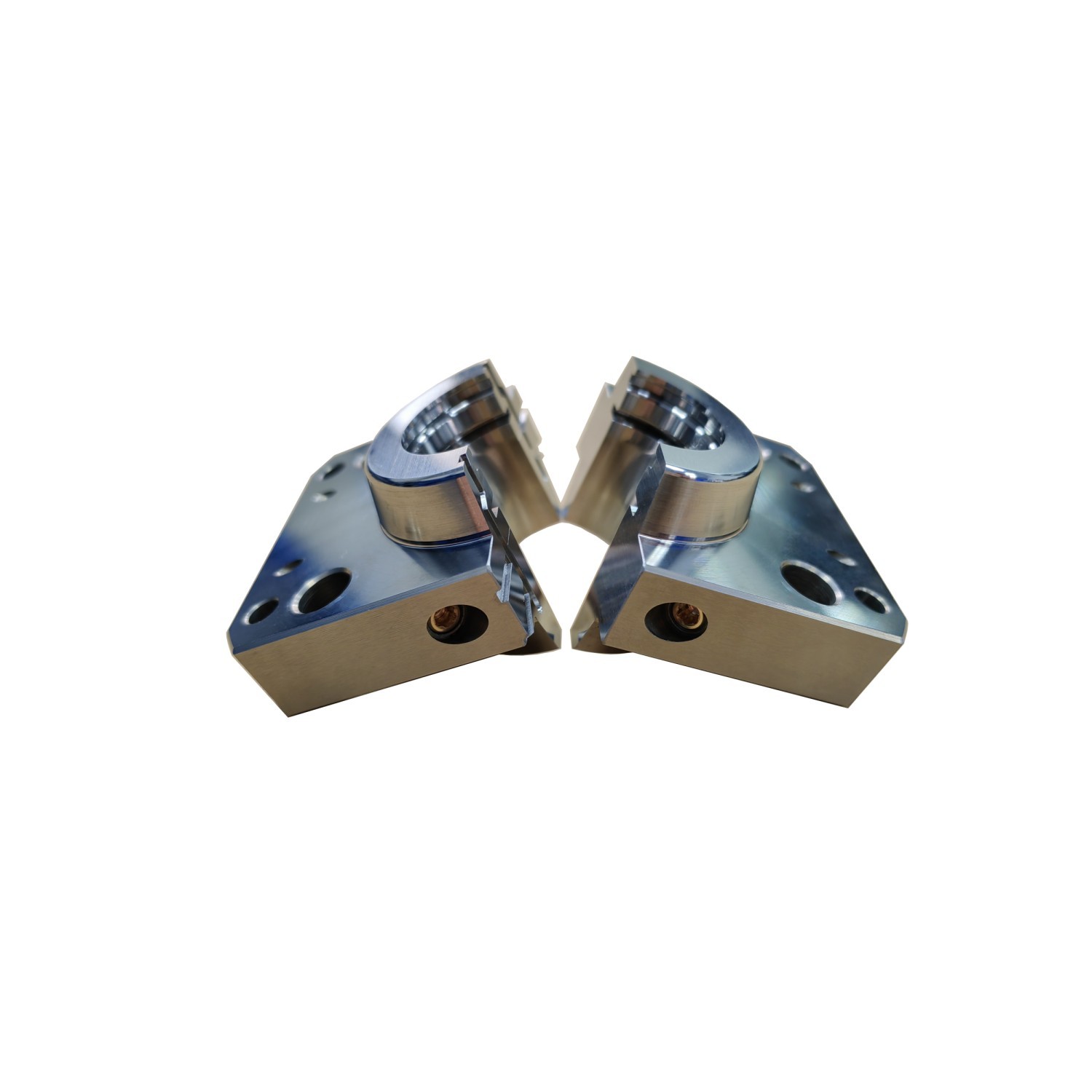

Rapid Changeover Design

Modular core inserts and standardized clamping slots enable sub-15-minute mold configuration switching.

Application Scenarios

Hot-Fill Tea & Juice Lines

Ensures bottle stability post-shrinkage in 85-95°C filling processes for ready-to-drink teas and NFC juices.

High-Acidity Beverage Packaging

Corrosion-resistant construction for citrus juices, vinegar-based drinks, and probiotic beverages.

Dairy Alternative Bottling

Maintains seal integrity for plant-based milk and yogurt drinks under frequent thermal cycling.

Cross-Border OEM Production

Cost-effective mold solution for Southeast Asian and African bottlers upgrading European-standard equipment.

Note

This product is engineered to be compatible with various injection molding systems and is not affiliated with or endorsed by any specific brand.

Service Process:

1. Sample-Based Workflow

① Customer provides sample → ② BJY Baijinyi conducts reverse engineering → ③ Deliver 2D/3D drawings for confirmation → ④ Confirmation completed → ⑤ Order placement → ⑥ Production workshop manufacturing → ⑦ Quality inspection → ⑧ Qualified shipment.

description2

Chinese

Chinese