0102030405

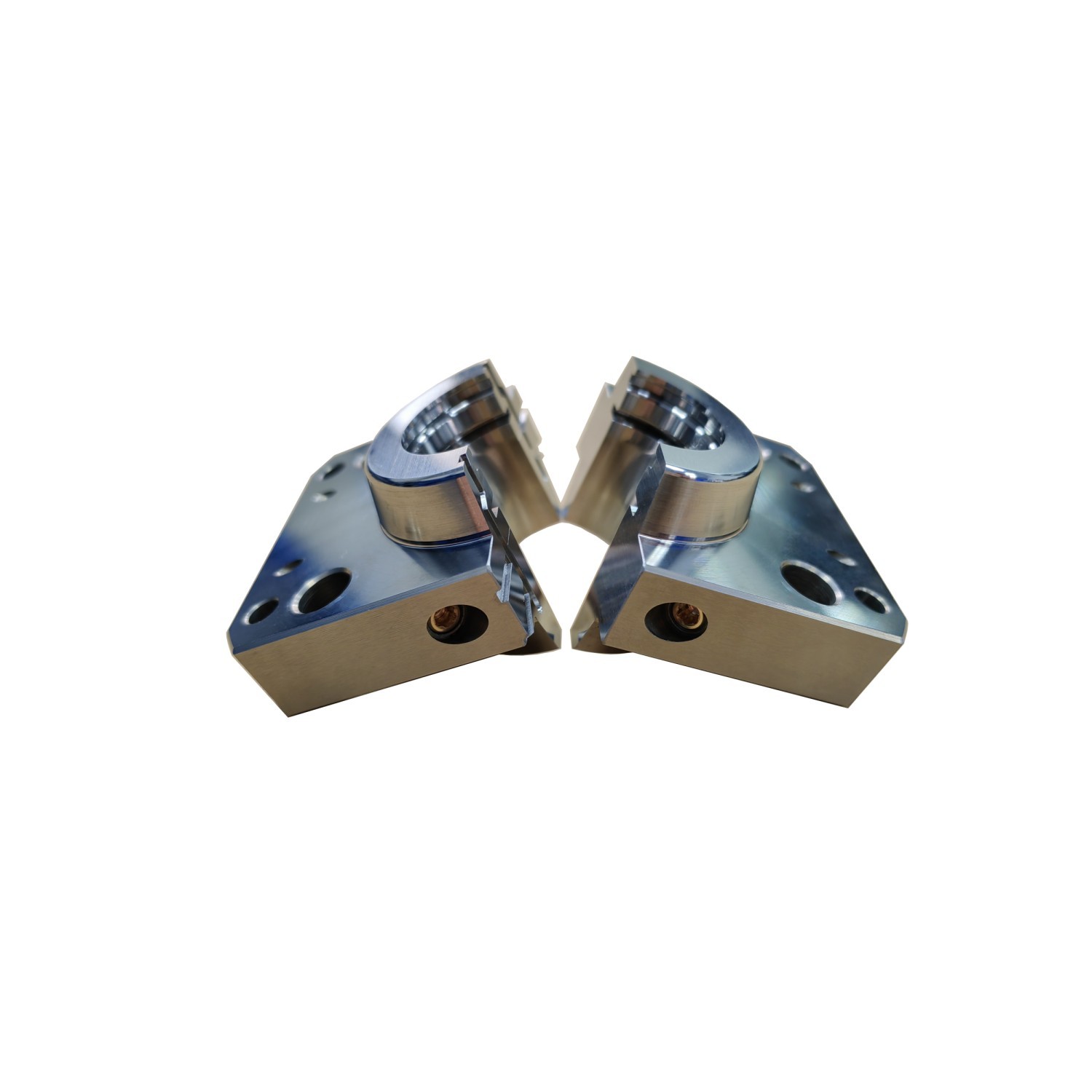

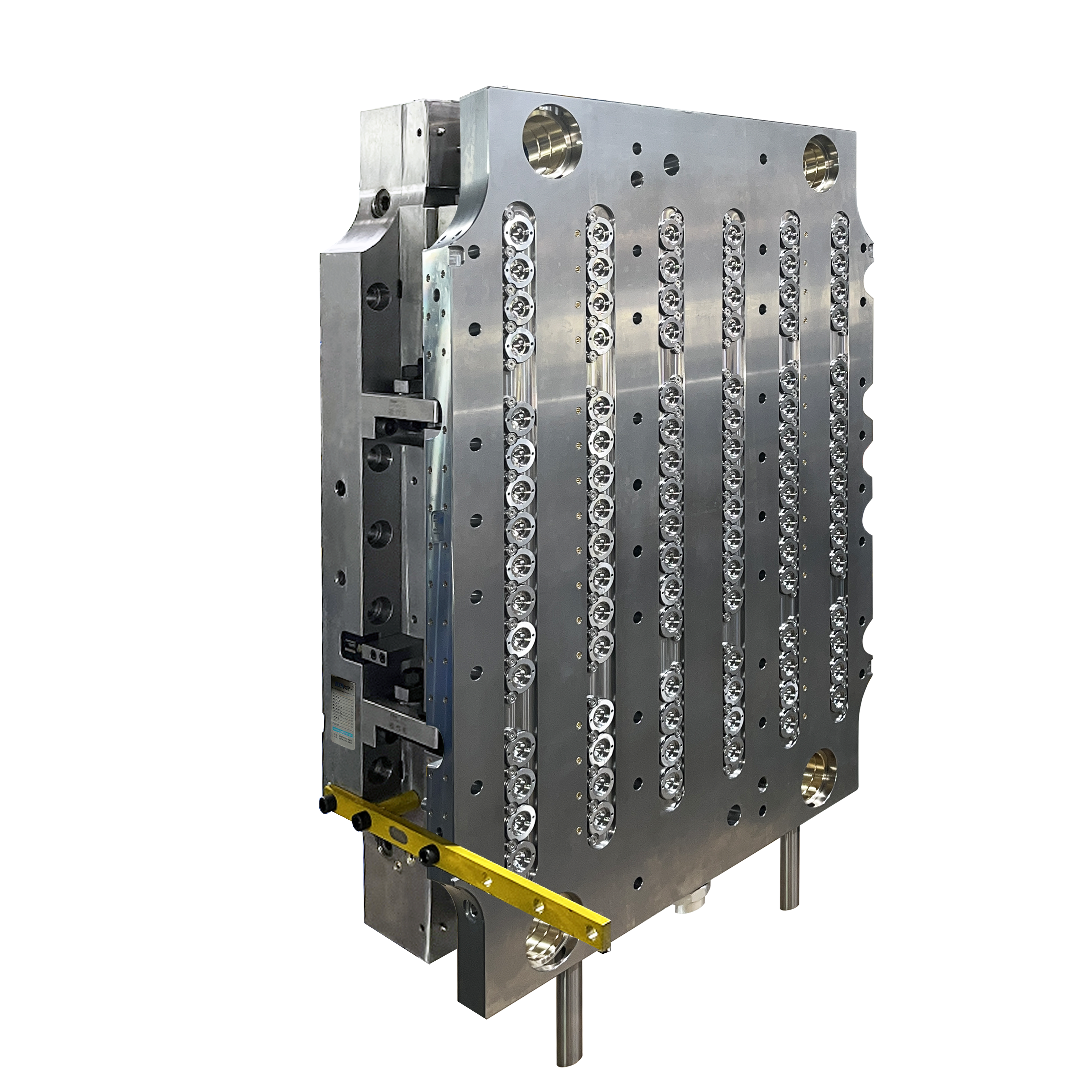

555ml Lightweight Aluminum Mold

Product Features

Outstanding Heat Dissipation:

High thermal conductivity of aluminum shortens the cooling cycle and boosts production efficiency.

Extended Service Life:

The hard anodized surface layer offers excellent wear and corrosion resistance, significantly increasing the mold’s lifespan.

Quick Changeover:

Modular design allows for mold changes in approximately 10 minutes, reducing downtime and improving productivity.

Lightweight Structure:

Lighter than traditional steel molds, making it easier to handle, transport, and maintain.

Smooth Surface Finish:

Uniform anodized coating ensures smooth preform release, effectively reducing defect rates.

Energy Efficient:

Optimized heat dissipation channels lower the consumption of compressed air and cooling water, contributing to overall energy savings.

Application Scenarios

1.Production lines for carbonated beverages, purified water, and juices.

2.Packaging for edible oils, condiments, and household daily chemicals.

3.Small-batch customization and OEM processing for pharmaceuticals and cosmetics.

4.R&D laboratories for sample production and process validation.

5.Upgrades and capacity expansion for small to medium-sized blow molding workshops aiming to reduce costs.

Service Process

1. Sample-Based Workflow

① Customer provides sample → ② BJY Baijinyi conducts reverse engineering → ③ Deliver 2D/3D drawings for confirmation → ④ Confirmation completed → ⑤ Order placement → ⑥ Production workshop manufacturing → ⑦ Quality inspection → ⑧ Qualified shipment.

description2

Chinese

Chinese