0102030405

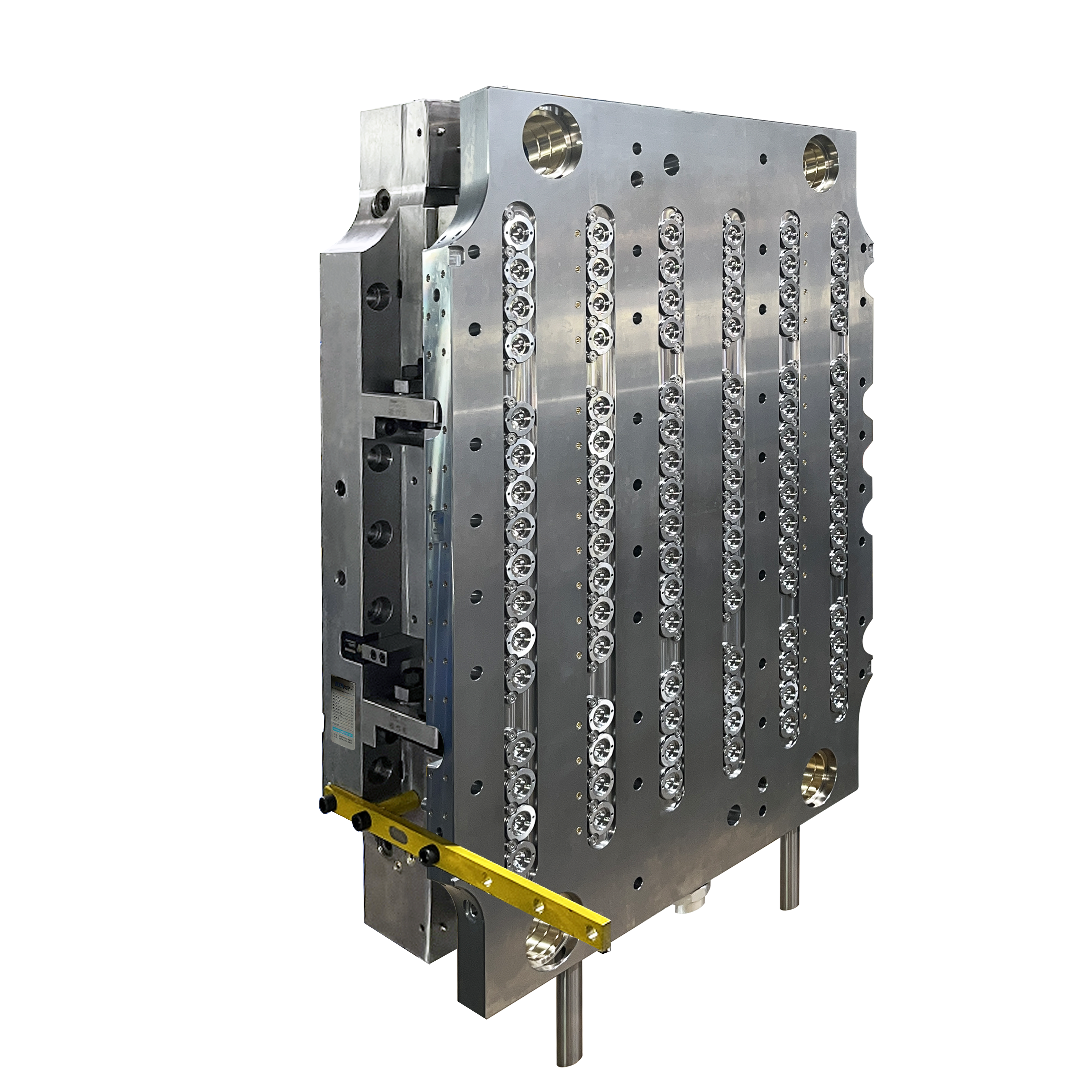

72 Cavities 48.2g PET Preform Injection Mold

Product Features

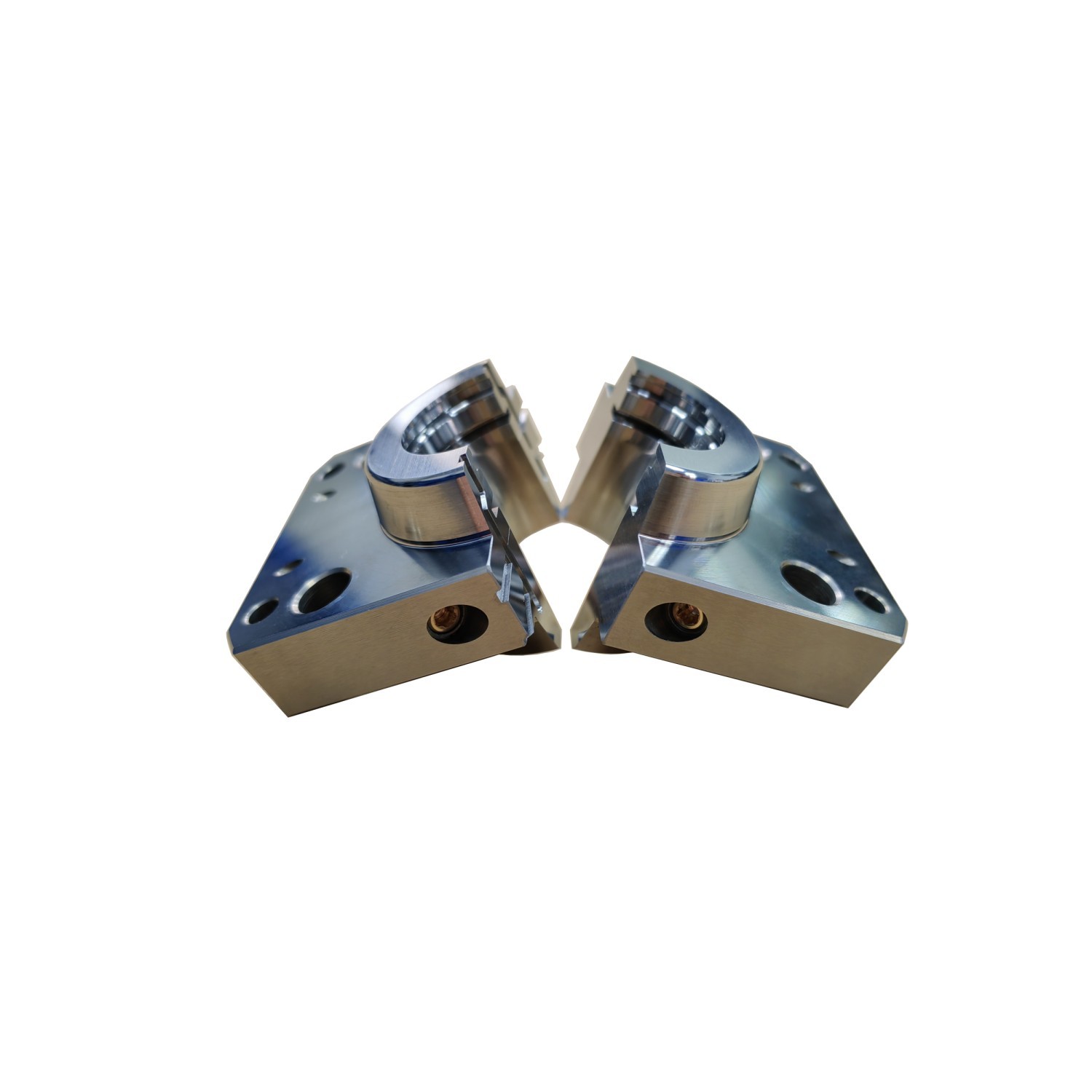

Precision Engineering:

Utilizes advanced CNC machining to achieve tight tolerances, ensuring uniform wall thickness and weight distribution across all preforms.

Optimized Cooling System:

Incorporates strategically designed cooling channels to expedite heat dissipation, thereby shortening cycle times and enhancing productivity.

High Durability:

Constructed from high-grade materials that withstand the rigors of continuous production, ensuring a prolonged service life.

Versatile Compatibility:

Designed to be compatible with a range of injection molding machines, facilitating easy integration into existing production lines.

Efficient Hot Runner System:

Features a balanced hot runner system that ensures uniform melt flow, reducing material waste and improving preform quality.

Application Scenarios

This mold is ideally suited for manufacturers in the beverage, food, and personal care industries seeking to produce 48.2g PET preforms with high efficiency and consistency. Its compatibility with various injection molding systems allows for flexible deployment across different production environments. Whether for mineral water bottles, carbonated drinks, or edible oil containers, this mold delivers reliable performance and quality.

Note

This product is engineered to be compatible with various injection molding systems and is not affiliated with or endorsed by any specific brand.

Service Process:

1. Sample-Based Workflow

① Customer provides sample → ② BJY Baijinyi conducts reverse engineering → ③ Deliver 2D/3D drawings for confirmation → ④ Confirmation completed → ⑤ Order placement → ⑥ Production workshop manufacturing → ⑦ Quality inspection → ⑧ Qualified shipment.

description2

Chinese

Chinese