0102030405

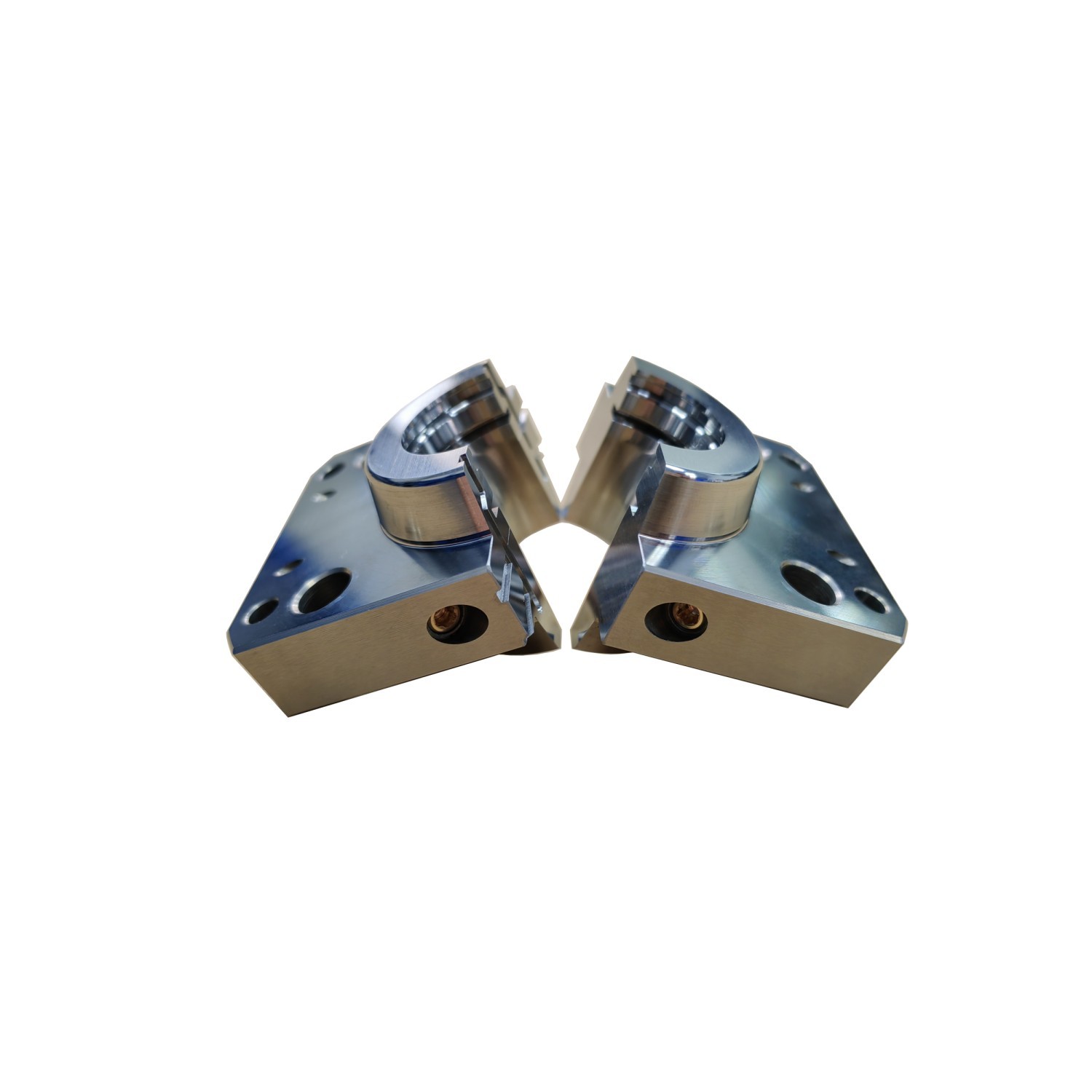

High-Precision PET Neck Ring Assembly

Product Selling Point Introduction

•Precision Interface Compatibility

Exclusively designed for 2925 Standard Interface (industry-standard specification), enabling plug-and-play installation without equipment modifications.

•High-Pressure Sealing Reliability

Optimized sealing surface structure and pressure distribution eliminate risks of filling leakage.

•Durability & Wear Resistance

Multi-layer composite hardening process withstands high-frequency operational wear, reducing maintenance requirements.

•Rapid Mold Change Compatibility

Modular interface design supports quick transitions between multiple bottle profiles on high-speed equipment.

Application Scenarios

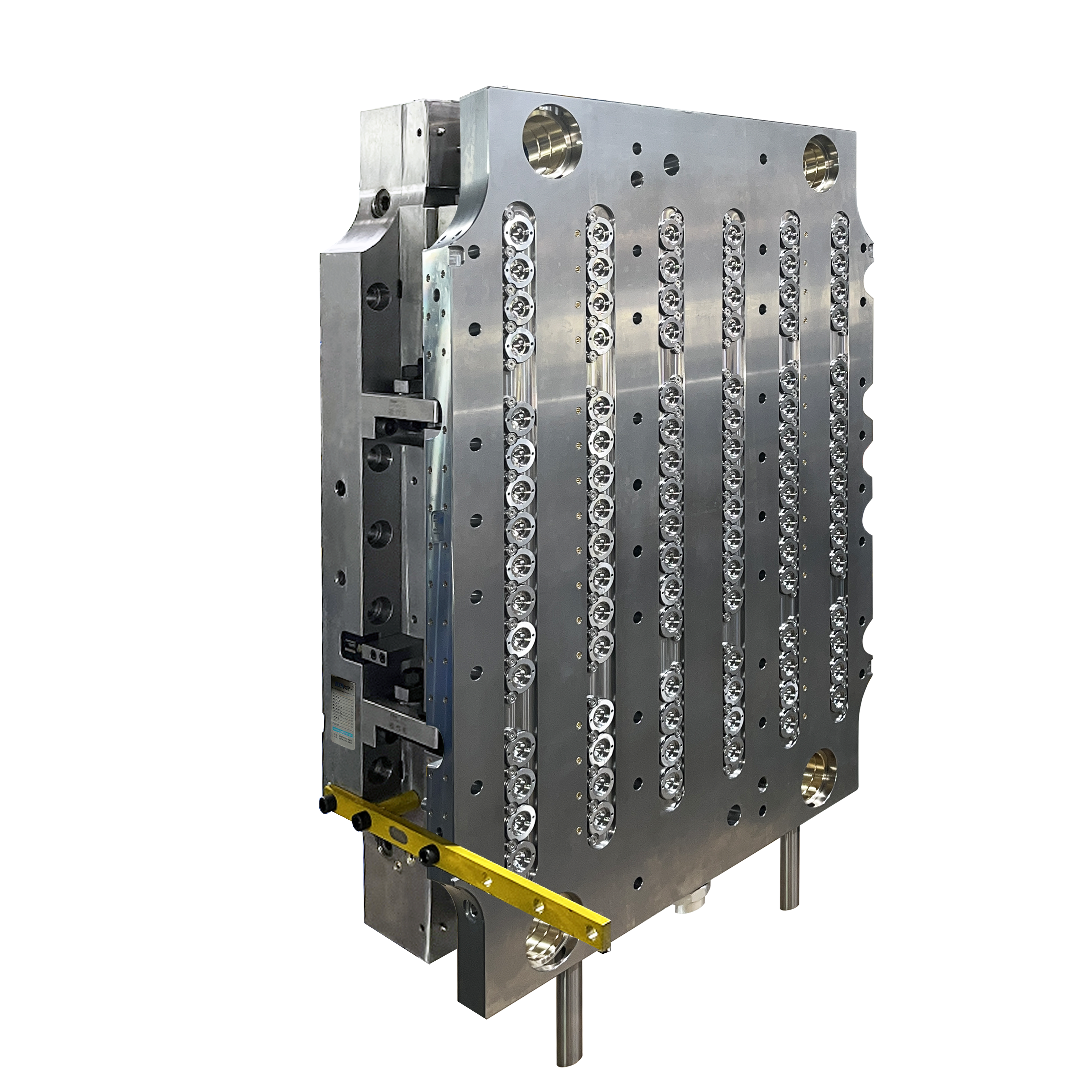

Specifically designed for beverage, juice, carbonated drink, and condiment production lines, particularly those requiring 13.5g neck specifications and 2925 Standard Interface compatibility. Addresses contract manufacturers' and brand owners' demands for equipment mold replacement, production line upgrades, or spare parts procurement, while supporting both hot-fill and cold-fill processes. Widely applied in liquid food packaging for bottled water, ready-to-drink tea, functional beverages, and similar products.

Service Process

1. Sample-Based Workflow

① Customer provides sample → ② BJY Baijinyi conducts reverse engineering → ③ Deliver 2D/3D drawings for confirmation → ④ Confirmation completed → ⑤ Order placement → ⑥ Production workshop manufacturing → ⑦ Quality inspection → ⑧ Qualified shipment.

2. Drawing/Data-Based Workflow

① Customer provides dimensions/drawings → ② Drawing verification → ③ Order placement → ④ Production workshop manufacturing → ⑤ Quality inspection → ⑥ Qualified shipment.

description2

Chinese

Chinese