0102030405

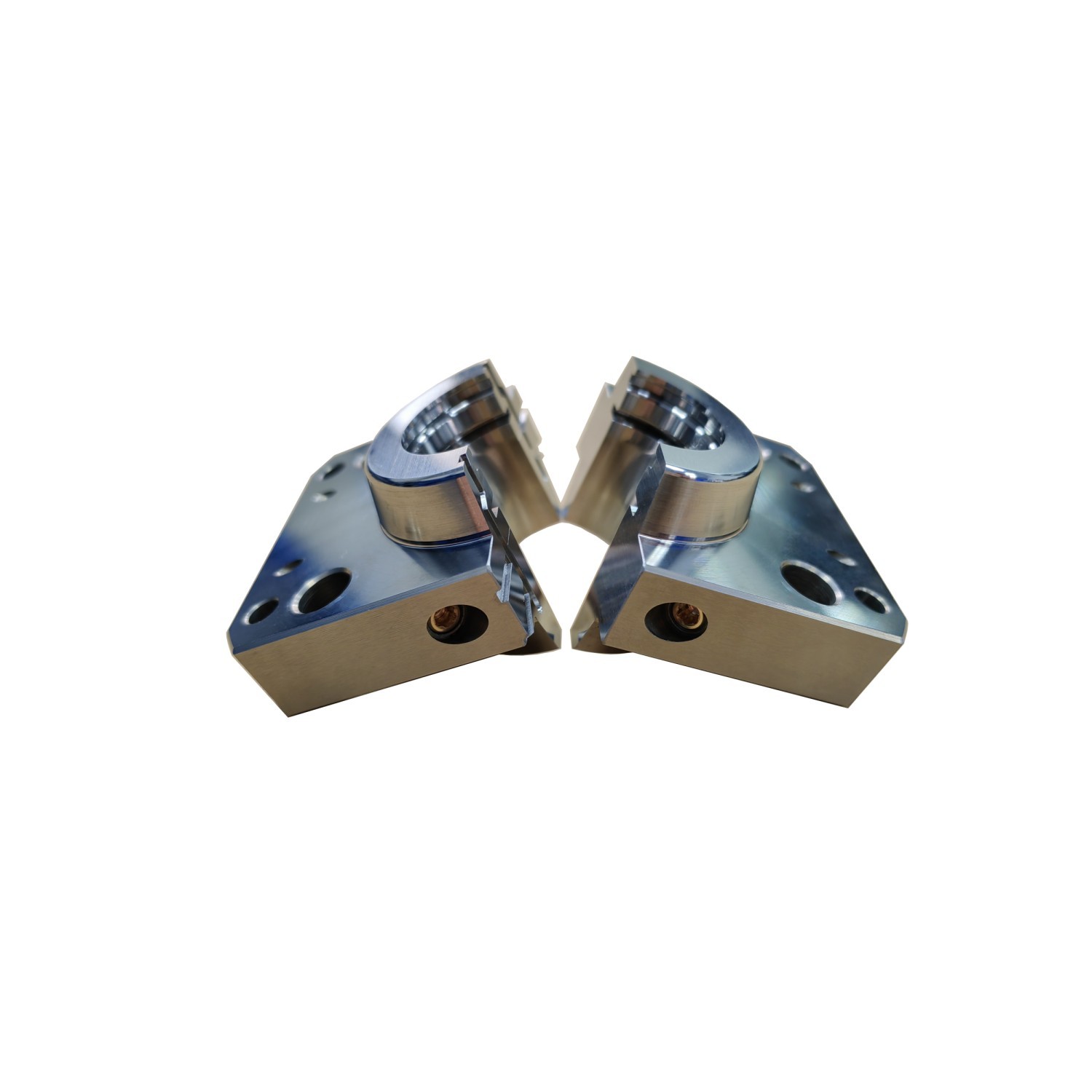

Limit Stopper

Product Features

Precision Limiting and Quick Adjustment

Designed to meet the requirements of various bottle types, the Limit Stopper ensures consistent stretch height of the stretch rod, maintaining uniform preform deformation. The modular structure allows for rapid disassembly and replacement without the need for complex tools or machine downtime, reducing production interruptions and enhancing equipment utilization.

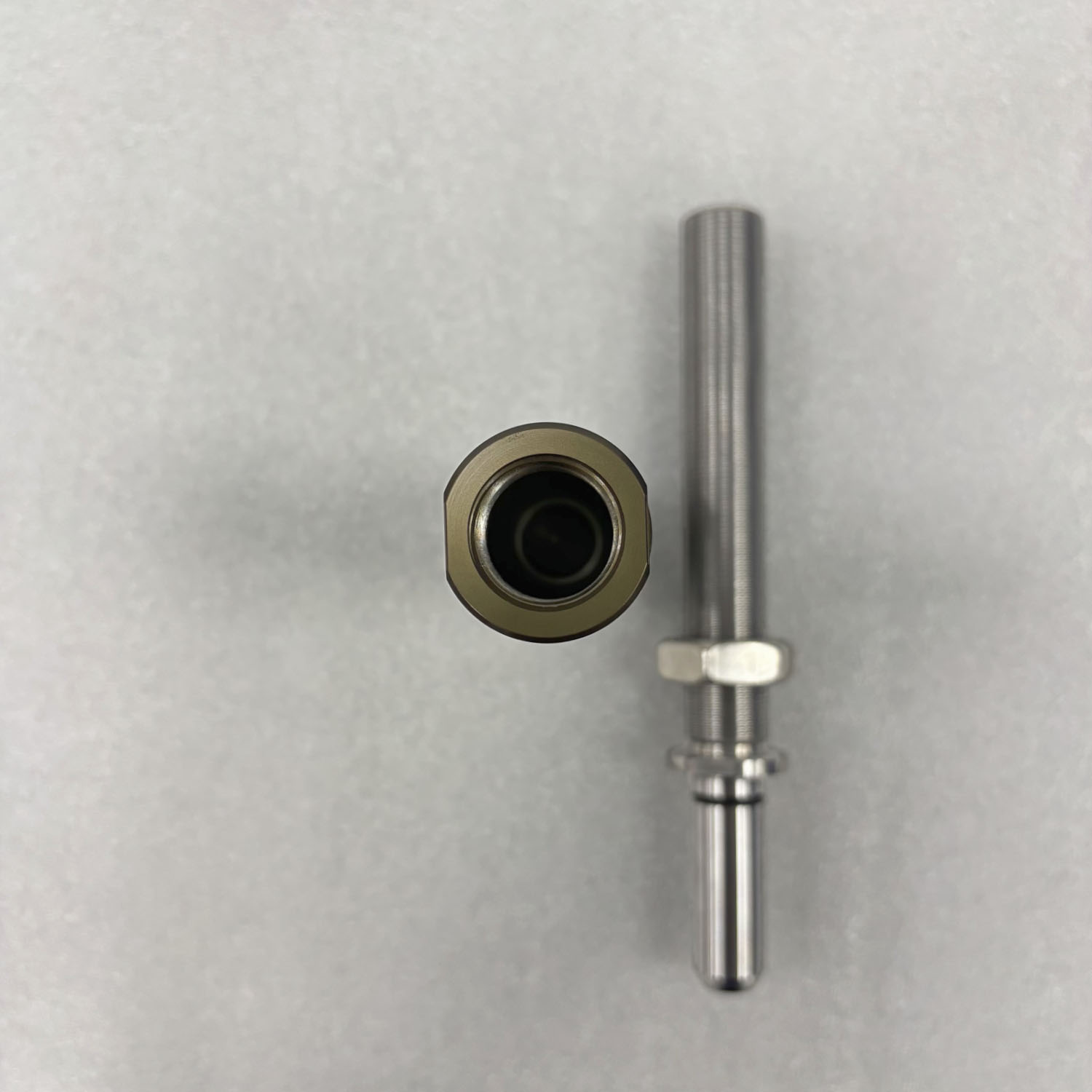

Wear Resistance and Long Service Life

The surface is engineered for enhanced resistance to wear and corrosion, enabling reliable performance under the high-temperature, high-pressure conditions of blow molding machines. Integrated buffer pads and sealing rings reduce mechanical impact damage and prevent dust or debris intrusion that could compromise functionality.

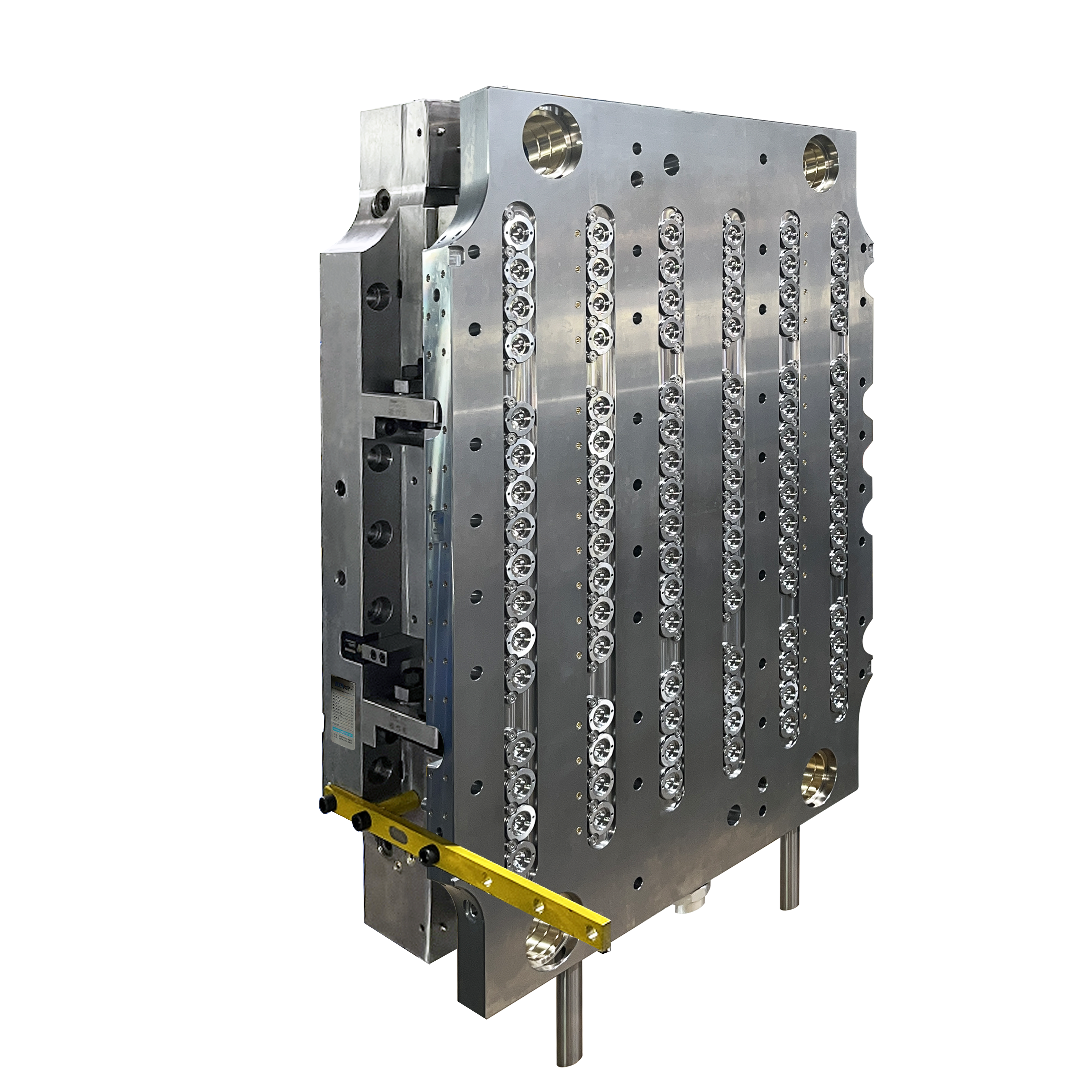

Compatibility

Supports a wide range of stretch rod interface standards (e.g., PCO 1881, ROPP), allowing seamless integration with blow molding machines from various brands. Custom dimensions and mounting options are available to meet specific application needs.

Easy Maintenance

Featuring a split-structure design, wear-prone components such as adjustment sleeves and limit blocks can be replaced independently, minimizing maintenance costs. Anti-slip textures and notched elements improve manual adjustment convenience and operational efficiency.

Application Scenarios

Food and Beverage Packaging:

Ideal for the blow molding of lightweight PET containers such as mineral water bottles and carbonated drink bottles. The limit stopper ensures uniform wall thickness and sufficient pressure resistance of the bottle body, meeting the stability requirements of high-speed production lines.

Personal Care and Pharmaceutical Industries:

Designed for precise stretching control of narrow-neck preforms used in cosmetic bottles and pharmaceutical containers. It guarantees neck sealing integrity and dimensional accuracy, fully complying with cleanroom production standards.

Industrial Packaging:

Applicable to the production of preforms for chemical liquid containers. The corrosion-resistant material design of the limit stopper enables reliable performance under harsh conditions involving strong acids and alkalis, ensuring long-term stable operation.

Service Process:

1. Sample-Based Workflow

① Customer provides sample → ② BJY Baijinyi conducts reverse engineering → ③ Deliver 2D/3D drawings for confirmation → ④ Confirmation completed → ⑤ Order placement → ⑥ Production workshop manufacturing → ⑦ Quality inspection → ⑧ Qualified shipment.

description2

Chinese

Chinese