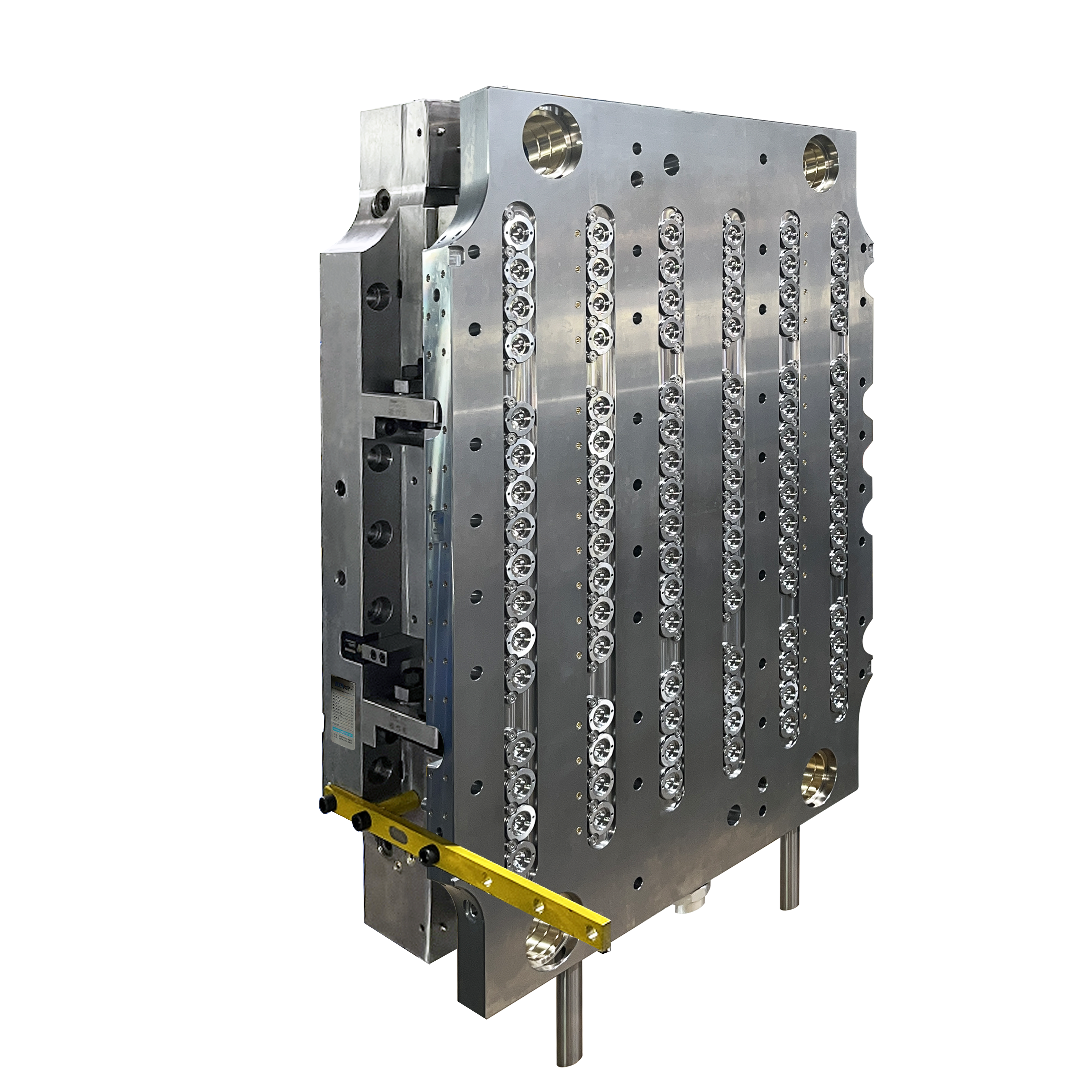

Mainstream Second-Generation PET Mold Shell Compatibility

Product Features

Application Scenarios

1. Carbonated Beverage Line Upgrades

——Direct Replacement Solution for Second-Generation High-Speed Systems

Designed for equipment users needing to replace aging mold shells in high-pressure carbonated bottle production (e.g., cola, sparkling water), this solution ensures zero line reconfiguration while maintaining OEM-standard performance.

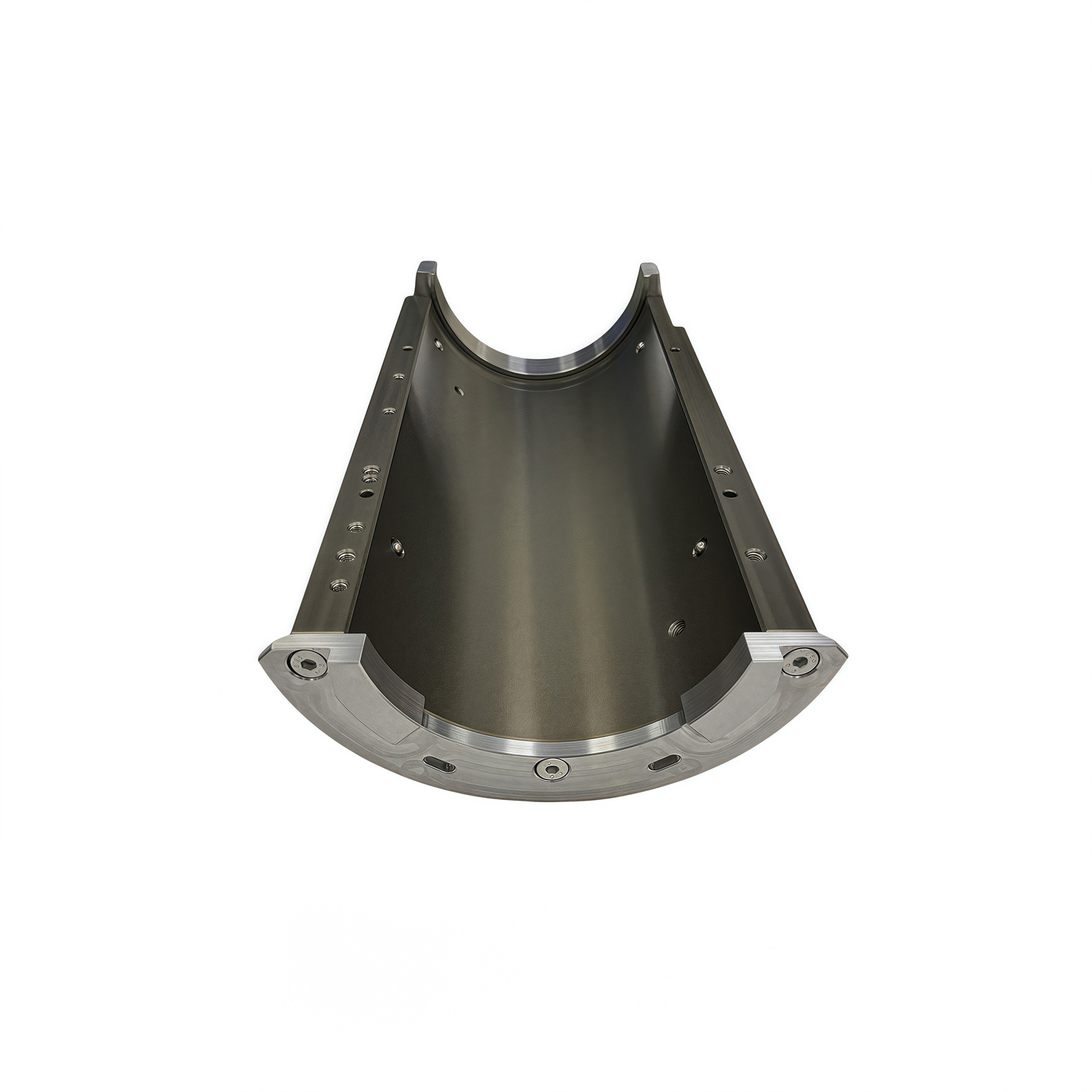

2.Hot-Fill Beverage Contract Manufacturing

——85-95°C Thermal Deformation Resistance

Engineered for hot-fill tea drinks and juices, the mold shell maintains bottle structural integrity and airtightness under prolonged thermal stress, ideal for herbal teas and NFC juice packaging.

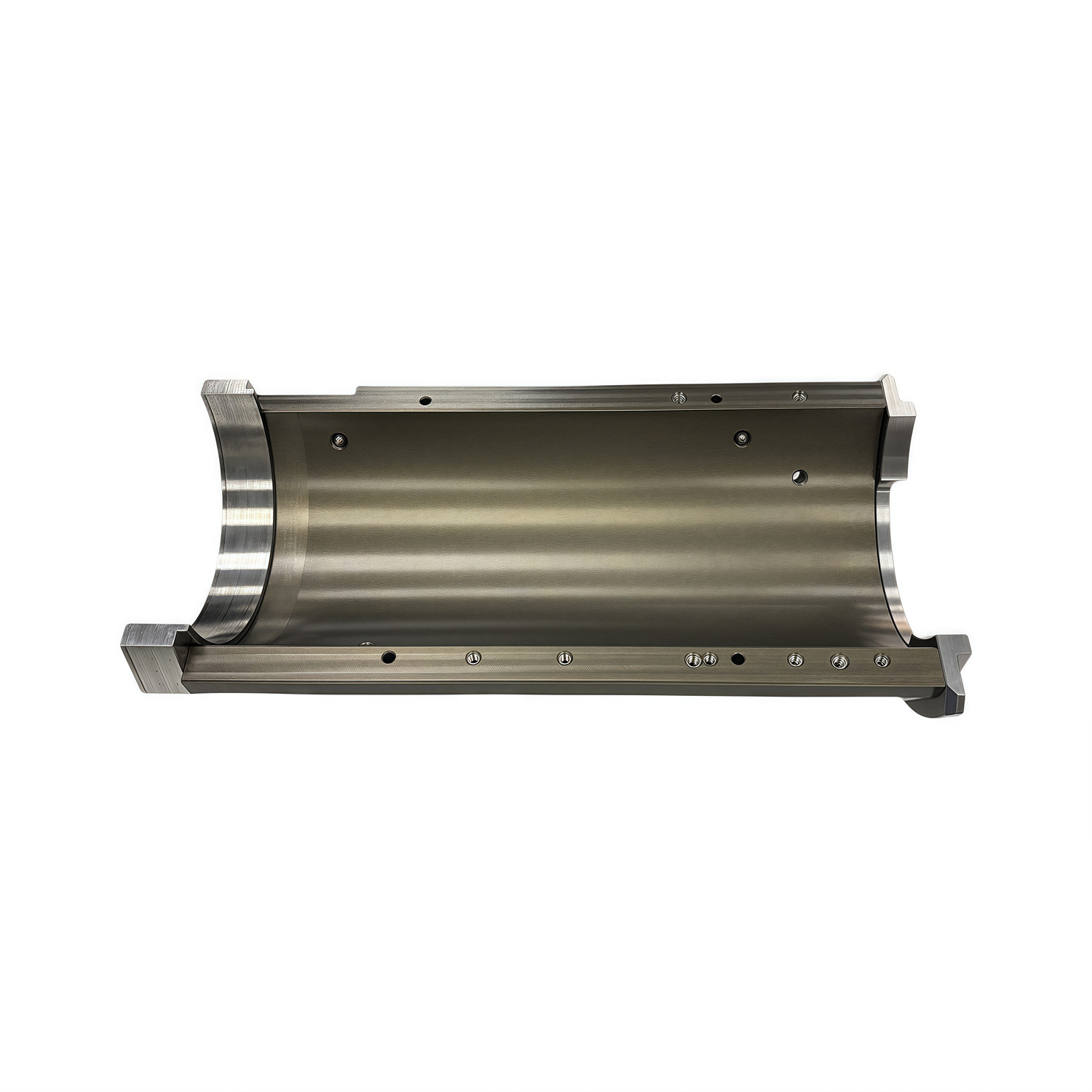

3.Dairy Packaging Expansion

——Viscous Liquid Compatibility

Features optimized bottle base support structure for yogurt and plant-based protein beverages, preventing deformation during high-viscosity liquid filling and capping.

Service Process

description2

Chinese

Chinese