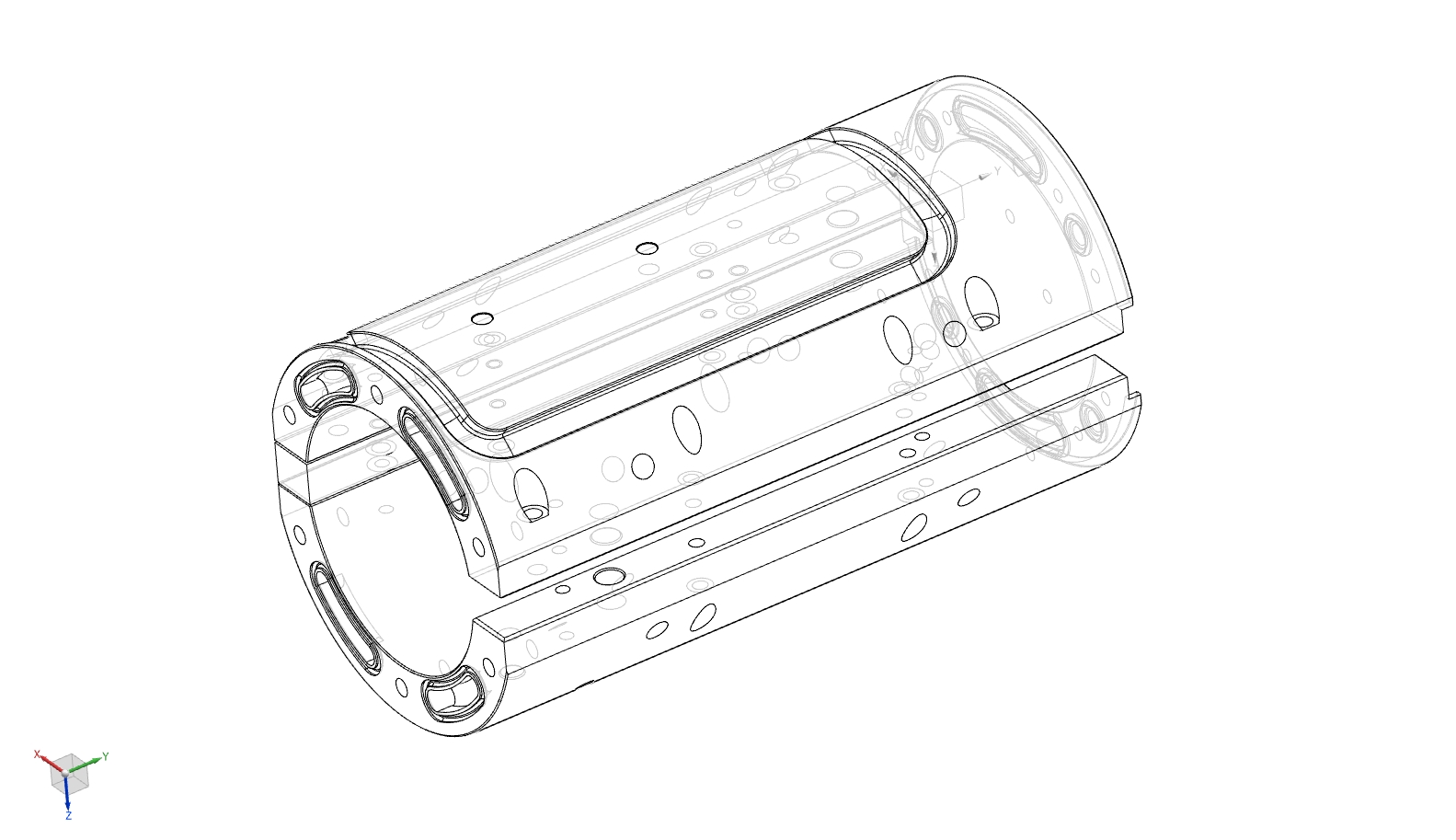

500ml Aluminum Blow Mold Shell for PET Bottles

Product Overview

This 500ml aluminum blow mold shell is engineered for high-precision PET bottle production. Crafted from premium aluminum alloys, it offers excellent thermal conductivity, ensuring rapid cooling and efficient manufacturing cycles. The mold's lightweight design facilitates easy handling and swift mold changes, enhancing operational efficiency. Its compatibility with various blow molding machines makes it suitable for producing bottles for beverages, food, and personal care products. The mold's surface undergoes anodized treatment, enhancing wear resistance and extending service life, even under high-volume production conditions. This product is designed to integrate seamlessly into diverse production lines, providing manufacturers with a reliable solution for consistent, high-quality PET bottle output.

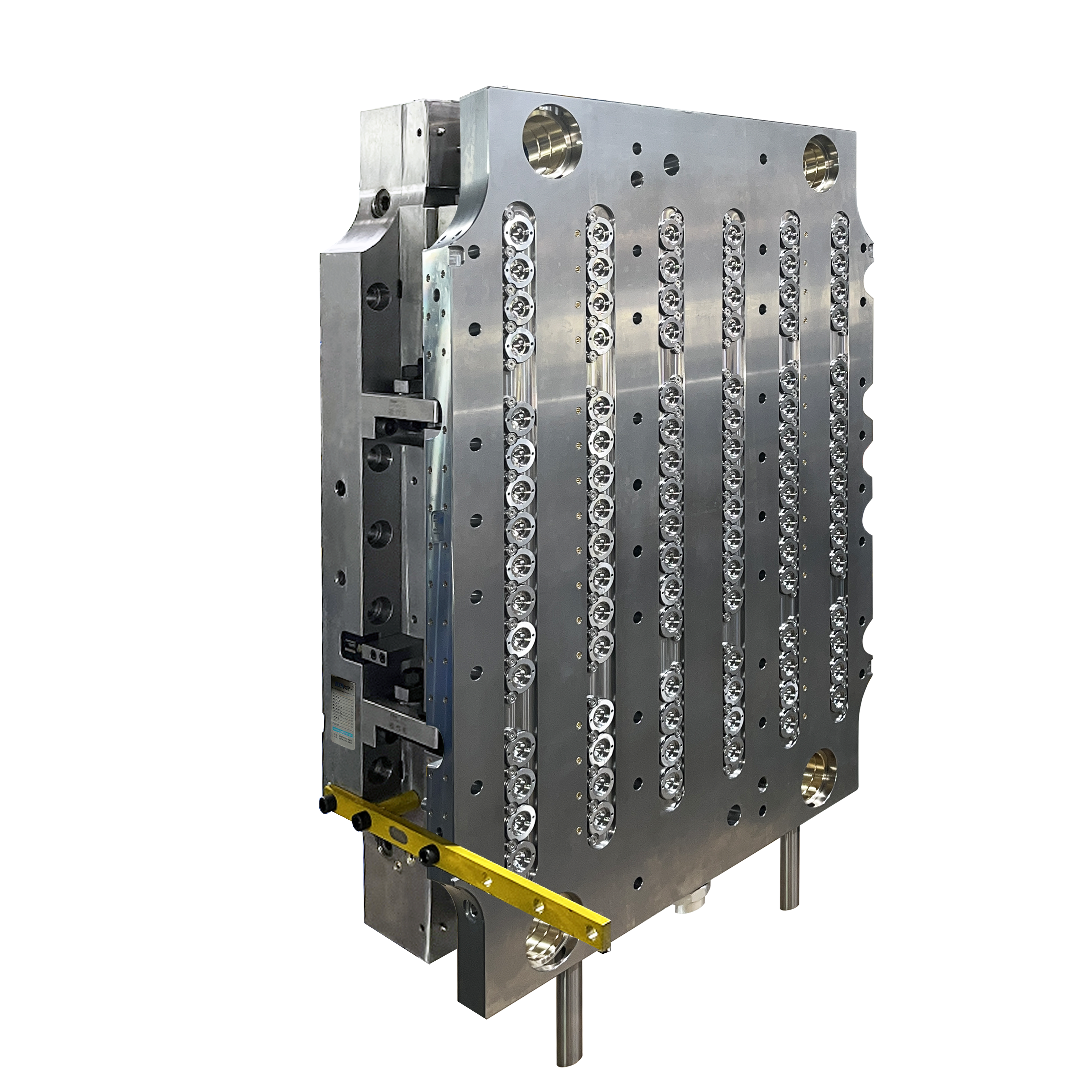

Mainstream Second-Generation PET Mold Shell Compatibility

——Precision Packaging System Integration

Precisely engineered to align with second-generation blow molding equipment's core specifications, this mold shell strictly complies with industry-standard interface protocols and structural guidelines. Utilizing precision CNC machining technology, it ensures seamless compatibility with high-speed production systems. Optimized for 500ml-2L PET bottle molding, even in demanding environments like carbonated beverage and hot-fill juice production, it guarantees:

1.Consistent wall thickness distribution

2.Reliable neck sealing performance

3.Uninterrupted production line stability

Delivers cost-efficient technical solutions for contract manufacturers and brand owners leveraging advanced blow molding technologies.

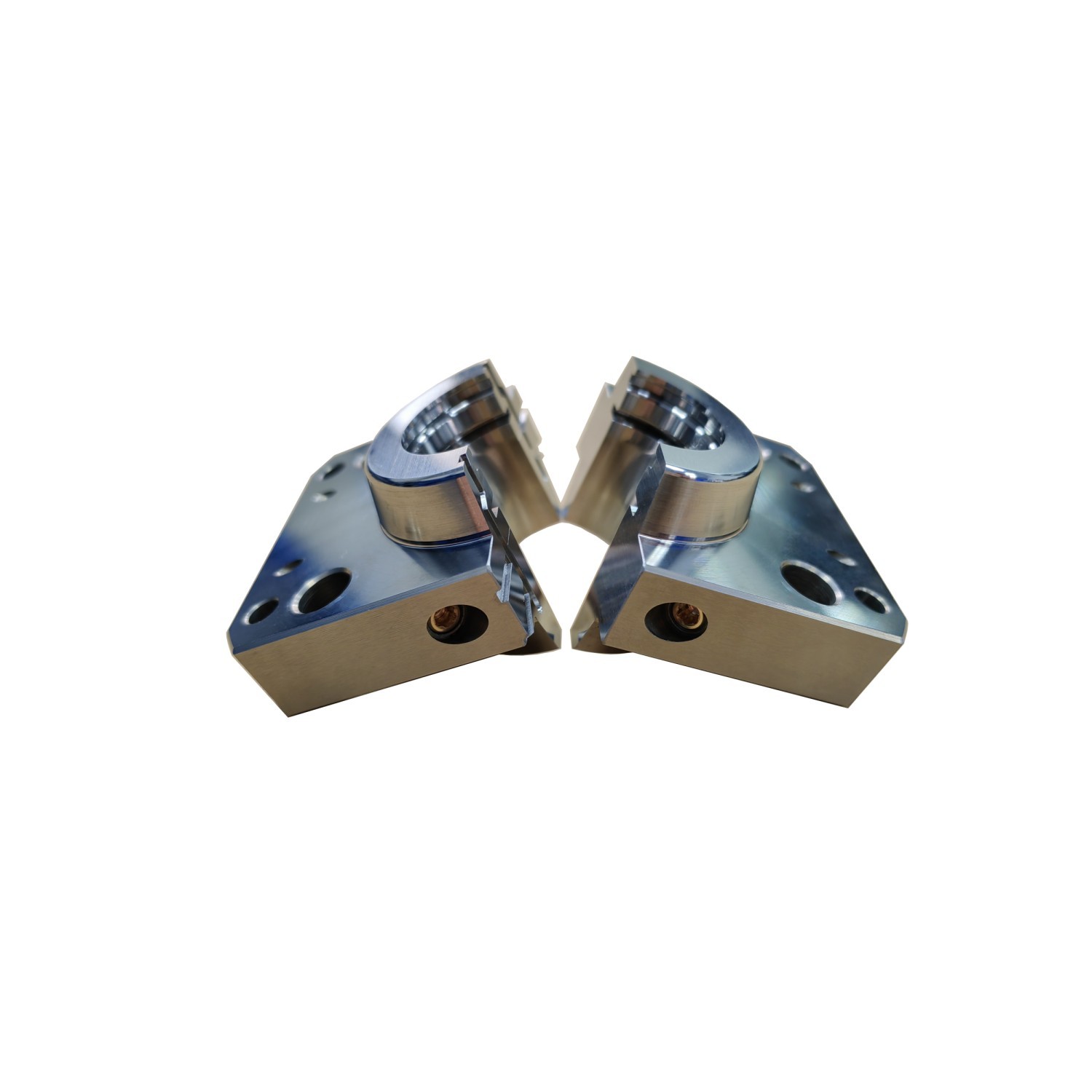

Mold Shell for Krones blowing machine

Mold Shell for PET Blowing Mold

Mold Shell is the most importance parts for Rotary PET blowing mold . It has the effect of rapid cooling. Because When the blowing mold is working, heat is generated, and if there is no cooling device, the mold is easily damaged, and the product forming will also be affected.

Chinese

Chinese