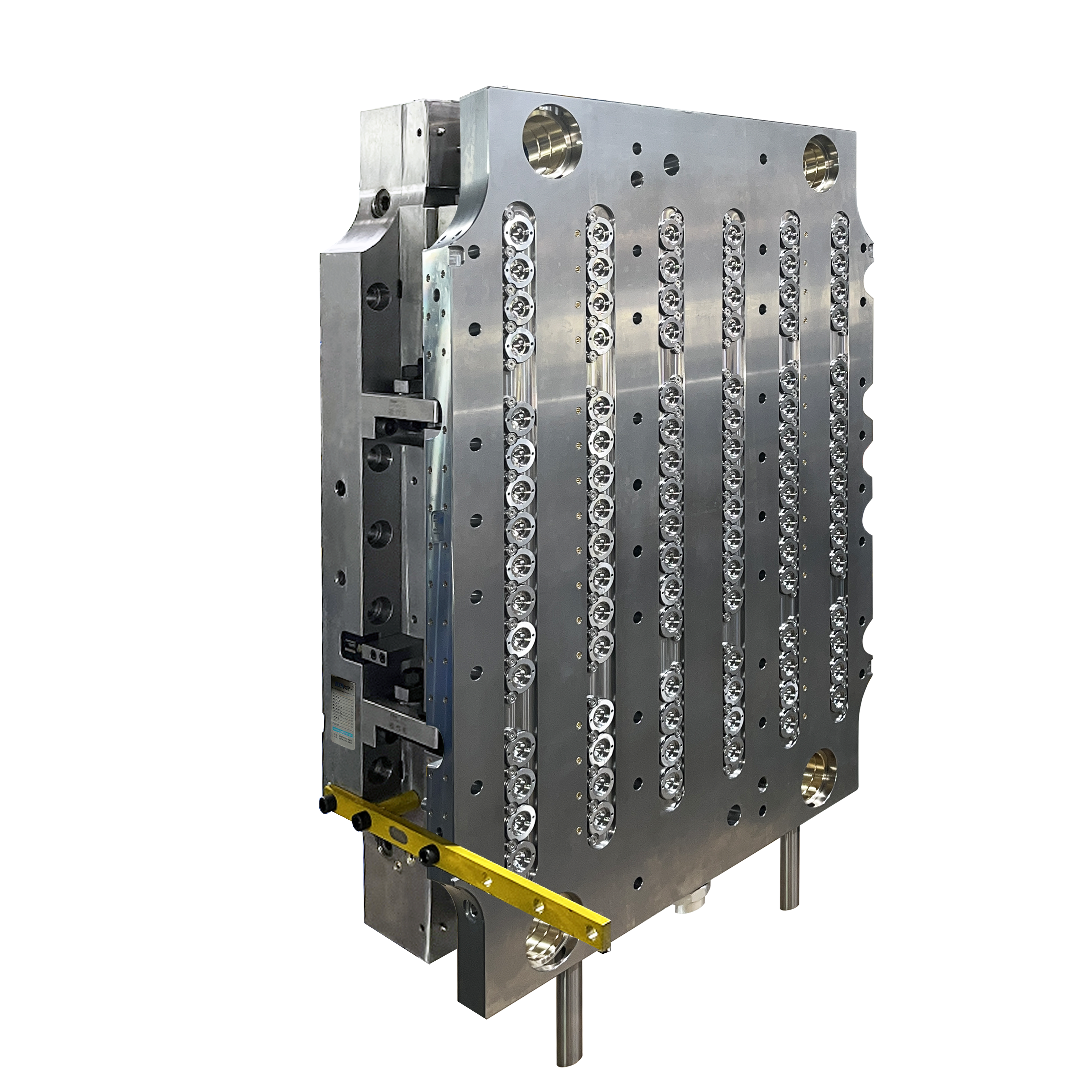

Limit Stopper

Product Overview

This limit stopper is specifically designed for the PET preform stretch-blow molding process. Its core function is to precisely control the stretching height of the stretch rod, ensuring consistent deformation parameters during bottle formation. This prevents common defects such as uneven wall thickness and insufficient mechanical strength caused by over- or under-stretching. The product adopts a modular mechanical structure, making it compatible with mainstream blow molding machine models. It is well-suited for the production of lightweight packaging bottles across the food and beverage, personal care, and pharmaceutical industries. By optimizing the limit adjustment mechanism and selecting highly wear-resistant materials, the limit stopper significantly enhances machine operational stability and extends mold service life.

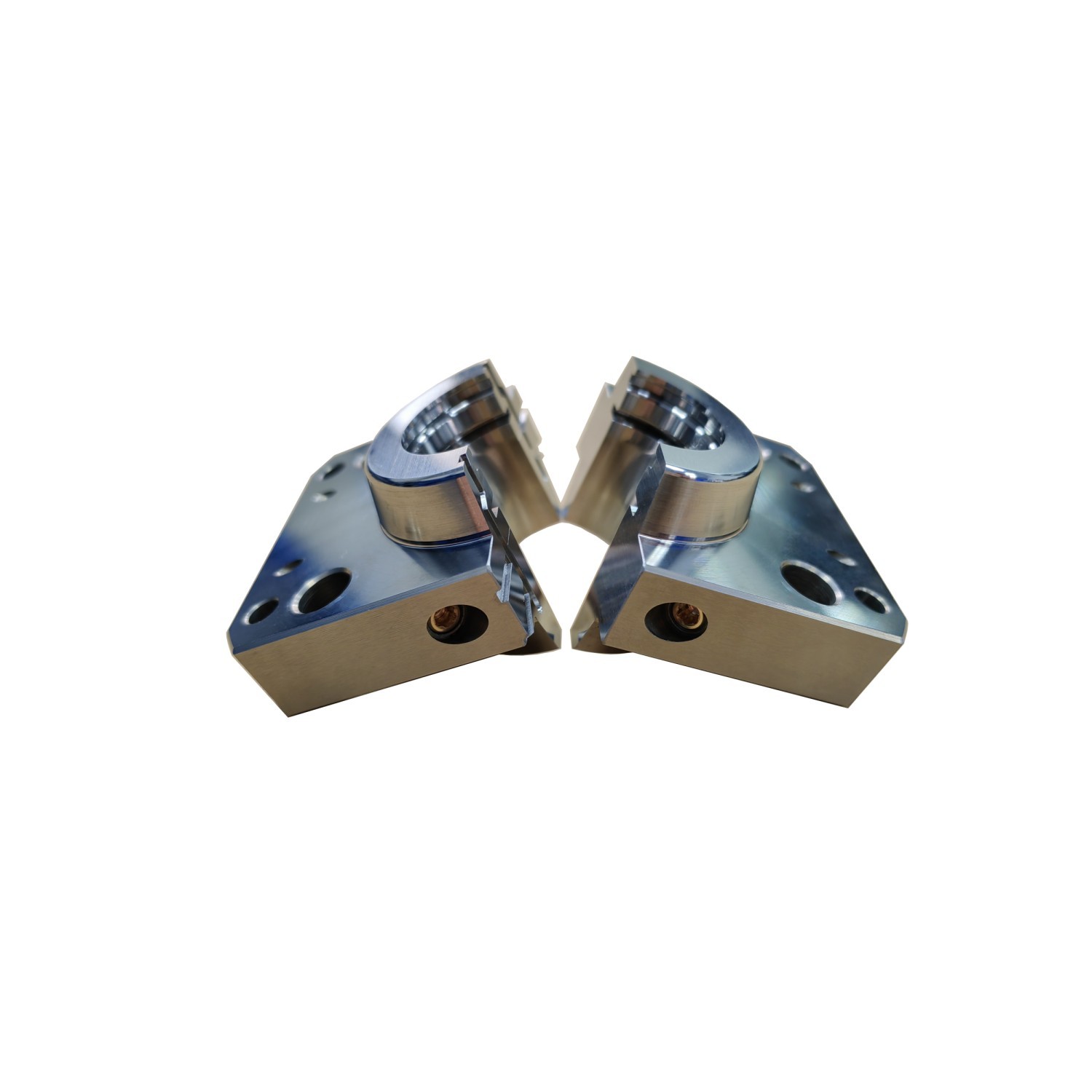

Bottle Gripper

Product Overview

This gripper assembly is specifically designed for PET blow molding machines and serves as a key execution component in automated production lines.

It is responsible for critical tasks such as preform gripping, transfer, and positioning. Made from high-strength alloy materials and manufactured with precision machining processes, it ensures stable clamping force and accurate positioning even under high-speed operation.

The modular design allows for quick replacement and easy maintenance, making it adaptable to different bottle types and production requirements, ultimately improving overall production efficiency.

High-Performance Thermal Insulation Plate for PET Blow Mold

Product Overview

Made from high-performance epoxy resin composite materials, it offers excellent thermal insulation properties and outstanding mechanical strength. Installed between the mold and the machine, it effectively blocks heat transfer, stabilizes mold temperature, improves product molding quality, and extends the service life of the equipment.

Chinese

Chinese