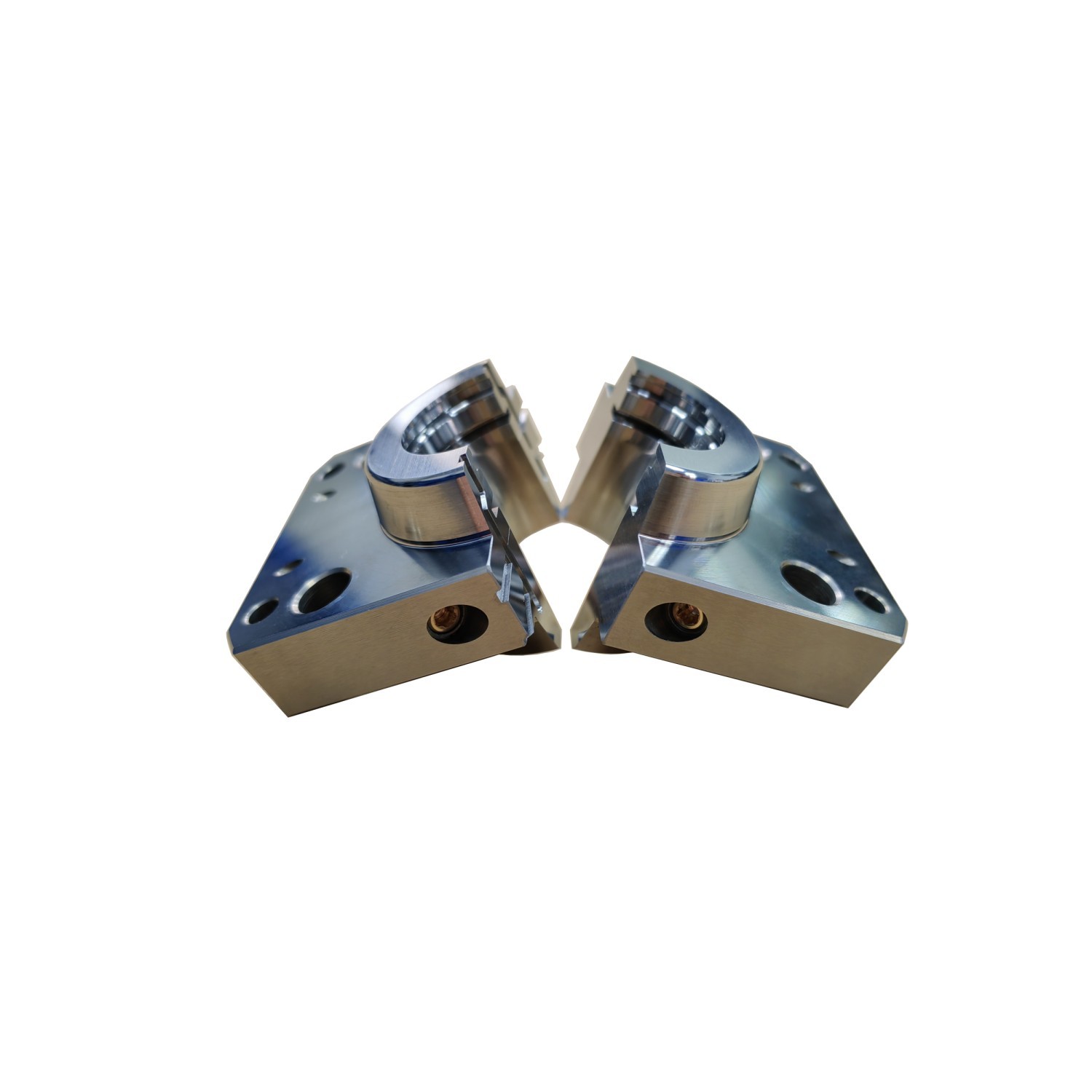

60g PET Neck Ring

Product Overview

This neck ring injection mold is specifically engineered for producing high-weight (60g) large-capacity preforms. Optimized for structural performance, it is ideal for applications in the food & beverage, edible oil, and personal care industries where thick-wall preforms are required.

The mold utilizes an advanced neck ring alignment system that significantly improves the machining efficiency of the cooling channels, reducing raw material waste while enhancing the uniformity of molten resin distribution and overall injection quality.

This solution effectively addresses common issues found in traditional neck ring designs, such as high processing costs and low dimensional accuracy due to complex geometries. It ensures consistent molding of high-gram preforms, meeting stringent demands for container strength and sealing performance in large-volume packaging.

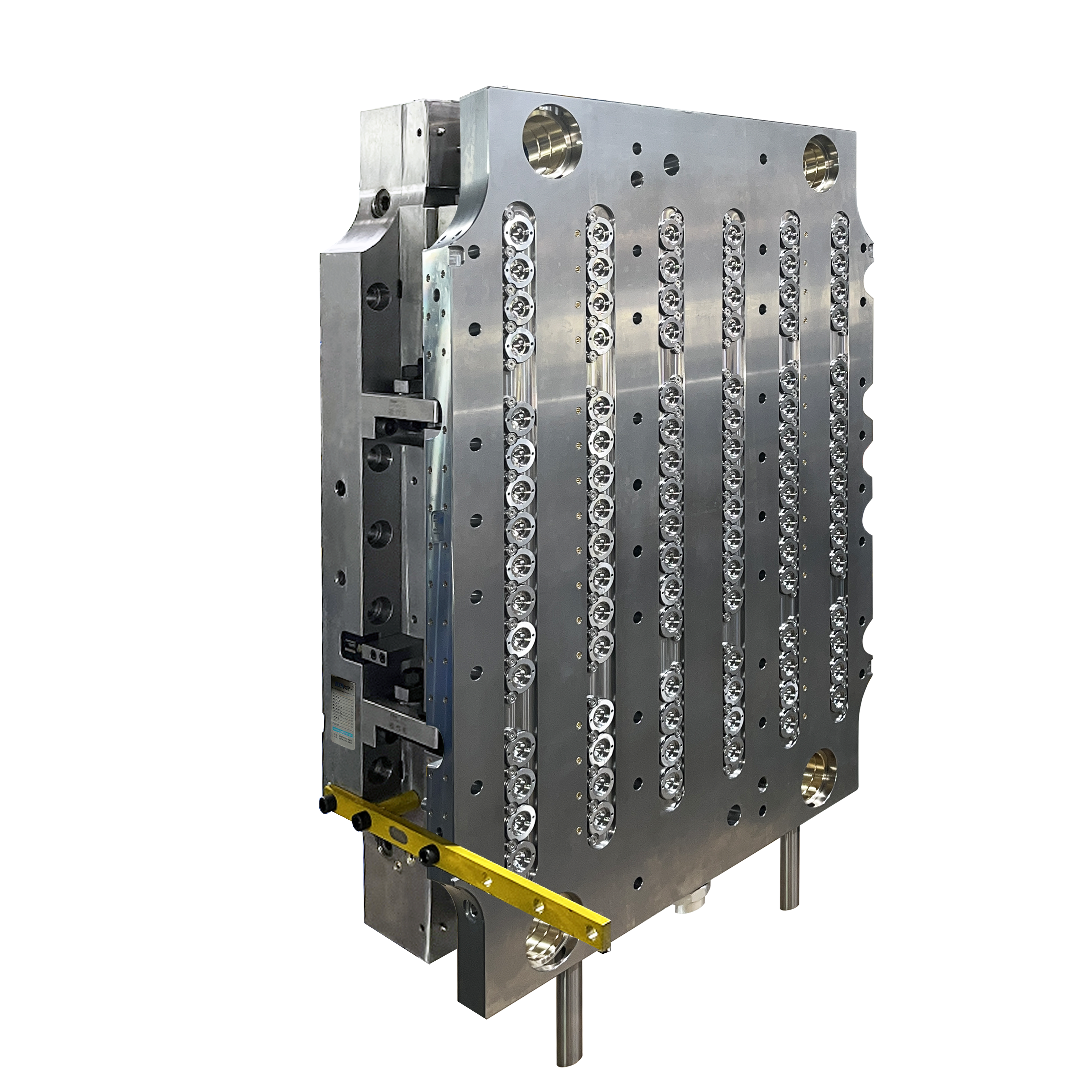

16.76g Cavity

Product Overview

This multi-cavity PET preform injection mold is specifically engineered for 16.76g standard-weight preforms. Featuring a modular hot runner system and precision machining technology, it is optimized for high-efficiency mass production across industries such as food, beverage, and personal care. The mold incorporates advanced industry-leading technologies to ensure high consistency in production. It is compatible with mainstream injection molding machines, supports rapid mold changeover, and integrates intelligent temperature control, significantly reducing cycle times while enhancing productivity and yield rates.

13.5g Lock Ring

Specifically designed for 13.5g PET preform injection molding, this Lock Ring complies with the industry-standard 2925 interface specifications. Crafted from steel material with 5-axis precision machining, it ensures precise alignment with hot runner systems in preform molds. Featuring a modular structure design, it seamlessly integrates with mainstream preform injection equipment while supporting both hot-fill and ambient-fill processes. Ideal for high-efficiency mass production scenarios in beverage and household chemical industries.

13.5g Cavity Flange

Specifically engineered for 13.5g PET preform injection molding, this cavity flange is compatible with mainstream preform system interface standards. Utilizing high-strength steel material and multi-axis precision machining technology, it ensures preform weight accuracy (≤0.3% deviation) and neck dimensional tolerance (±0.02mm). Featuring a modular design, it seamlessly integrates with various hot runner systems of injection molding equipment, meeting the core demands of beverage and household chemical industries for high-efficiency mass production and molding consistency. Compatible with both hot-fill and ambient-fill processes.

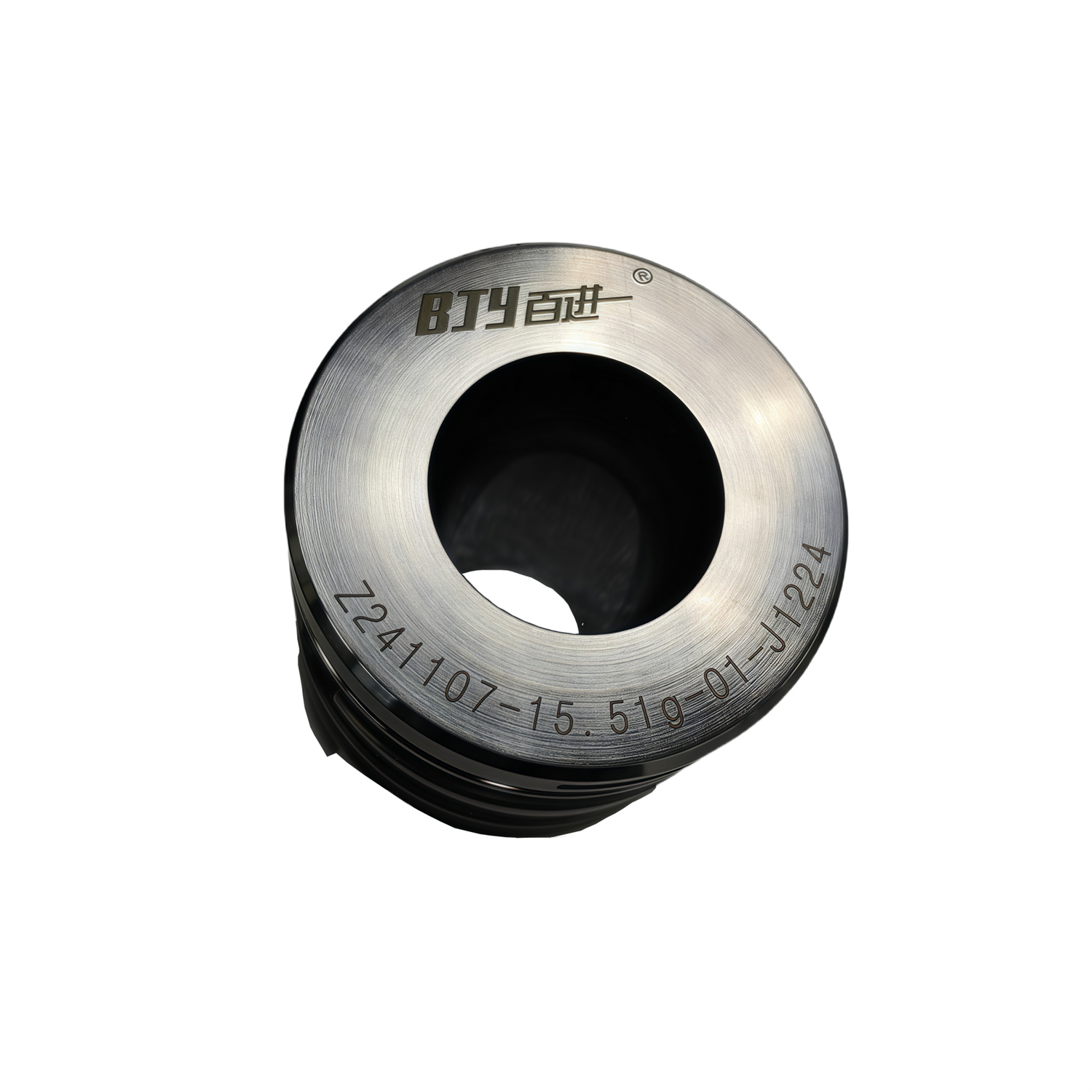

15.51g Cavity

——Precision Packaging System Integration

This mold cavity component is specifically engineered to achieve seamless integration with industrial-grade injection molding equipment, optimized for 15.51g PET preform molding standards. It strictly adheres to industry-recognized system interface parameters and advanced clamping logic, utilizing high-hardness steel material and multi-axis precision machining technology to ensure flawless compatibility with high-performance injection systems. Designed to meet the stringent requirements of high-speed production lines—including uniform preform wall thickness and neck dimensional accuracy (≤±0.02mm)—it delivers reliable solutions for mass production of PET preforms in beverage, personal care, and household chemical industries, enabling efficient and stable equipment adaptation without operational downtime.

High-Precision PET Neck Ring Assembly

——Compatible with 2925 Standard Encapsulation System

Specifically designed for industry-standard bottle neck encapsulation systems, this neck ring assembly ensures plug-and-play compatibility with mainstream high-speed filling equipment. Crafted from high-strength alloy steel and anti-wear coating technology, it guarantees long-term stable operation under high-temperature and high-pressure conditions, ideal for precise PET bottle neck encapsulation in beverage and dairy industries. Addresses manufacturers' critical demands for airtight sealing, production efficiency, and mold compatibility without retrofitting.

Spare Parts for Injection Machine

Catering to PET molding needs, essential for efficient production in various industries. Our products applicable for Huksy,Netstal,Sipa,Krauss Maffei,Huayan etc injection machines,boast durability, precision, and compatibility, ensuring seamless operations. Elevate your injection process today!

Chinese

Chinese